برقی تقسیم کارے کے نظام میں ٹرانسمیشن اور تقسیم کی ضروریات کے مطابق وولٹیج کی سطح کو بڑھانے یا کم کرنے کے لیے ٹرانسفارمرز کا بہت زیادہ انحصار ہوتا ہے۔ دستیاب مختلف اقسام کے ٹرانسفارمرز میں، تیل میں ڈوبا ہوا ٹرانسفارمر درمیانی سے لے کر زیادہ وولٹیج کی درخواستوں کے لیے سب سے زیادہ اپنائے گئے حل میں سے ایک ہے۔ یہ مضبوط برقی آلات معدنی تیل کو عایق وسیط اور تبريد کے عامل کے طور پر استعمال کرتے ہیں، جس کی وجہ سے وہ بجلی کے جال، صنعتی سہولیات اور دنیا بھر میں یوٹیلیٹی سب اسٹیشنز میں ضروری اجزاء بن جاتے ہی ہیں۔

ان ٹرانسفارمرز میں تبريد کا میکانزم آپریشنل کارکردگی کو برقرار رکھنے اور آلات کی خرابی کو روکنے میں ایک اہم کردار ادا کرتا ہے۔ ان تبريد کے نظاموں کے کام کرنے کے طریقہ کار کو سمجھنا بجلی کے انجینئرز، سہولیات کے مینیجرز اور وہ ماہرین جو ہائی وولٹیج بجلی کے آلات کے ساتھ کام کرتے ہیں، کے لیے قیمتی بصیرت فراہم کرتا ہے۔ تکنیکی تبريد کے عمل یہ یقینی بناتے ہیں کہ ٹرانسفارمرز بھاری بجلی کے بوجھ کو سنبھال سکیں جبکہ اپنی مکمل خدمت کی مدت کے دوران محفوظ آپریٹنگ درجہ حرارت برقرار رکھیں۔

جدید بجلی کی بنیادی ڈھانچہ مختلف لوڈ کی حالتوں اور ماحولیاتی عوامل کے تحت قابل اعتماد ٹرانسفارمر کی کارکردگی کا تقاضا کرتا ہے۔ تبريد کے نظام کی ڈیزائن براہ راست ٹرانسفارمر کی گنجائش، کارکردگی کی درجہ بندیوں اور مجموعی عمر پر اثر انداز ہوتی ہے۔ تیل میں غوطہ زد ٹرانسفارمر تبريد کے میکانزم کے پیچھے بنیادی اصولوں کا جائزہ لے کر، ماہرین آلات کے انتخاب، انسٹالیشن کی ضروریات اور دیکھ بھال کے طریقہ کار کے بارے میں مستند فیصلے کر سکتے ہیں۔

تیل میں غوطہ زد ٹرانسفارمرز میں بنیادی تبرید کے اصول

قدرتی کنویکشن کا عمل

تیل میں غوطہ زد ٹرانسفارمرز میں بنیادی تبرید کا طریقہ ٹرانسفارمر ٹینک کے اندر درجہ حرارت کے فرق سے پیدا ہونے والی قدرتی کنویکشن کرنٹس پر منحصر ہوتا ہے۔ جب وائنڈنگز کے ذریعے بجلی کا کرنٹ بہتا ہے، تو مزاحمتی نقصانات سے حرارت پیدا ہوتی ہے جسے عزل کے ٹوٹنے اور اجزاء کی خرابی کو روکنے کے لیے منتشر کرنا ضروری ہوتا ہے۔ ٹرانسفارمر کے مرکز اور وائنڈنگز کے اردگرد موجود تیل اس حرارتی توانائی کو جذب کر لیتا ہے، جس کی وجہ سے اس کا درجہ حرارت بڑھ جاتا ہے اور کثافت کم ہو جاتی ہے۔

گرم تیل قدرتی طور پر ٹرانسفارمر ٹینک کی اوپری سطح کی طرف اٹھتا ہے جبکہ ٹھنڈا تیل حرارت پیدا کرنے والے اجزاء کے قریب آ کر اس کی جگہ لیتا ہے۔ اس مسلسل گردش کے نمونے سے مسلسل حرارتی حرکت پیدا ہوتی ہے جو وائنڈنگز اور کور سے ٹینک کی دیواروں اور خارجی تبرید سطحوں تک حرارتی توانائی کو منتقل کرتی ہے۔ اس قدرتی مسلسل حرکت کی کارکردگی تیل کی لیسیت، ٹینک کی ہندسی شکل اور گرم اور ٹھنڈے علاقوں کے درمیان درجہ حرارت کے فرق جیسے عوامل پر منحصر ہوتی ہے۔

ٹینک کی ڈیزائن قدرتی مسلسل حرکت کے بہاؤ کے نمونوں کو بہتر بنانے میں اہم کردار ادا کرتی ہے۔ تیار کنندہ اندرونی بیفل کی ترتیب اور تیل کے بہاؤ کے راستوں کو احتیاط سے ڈیزائن کرتے ہیں تاکہ موثر حرارتی منتقلی کو فروغ دیا جا سکے جبکہ اس انتشار کو کم کیا جا سکے جو تبرید کی مؤثریت کو کم کر سکتا ہے۔ ٹرانسفارمر ٹینک کی دیواریں حرارت کو بکھرنے کی اہم سطحیں ہوتی ہیں، جو اردگرد کی ماحولیاتی ہوا کو تابکاری اور مسلسل حرکت کے ذریعے حرارتی توانائی منتقل کرتی ہیں۔

حرارت منتقلی کے طریقے

تیل میں غرق ٹرانسفارمرز میں حرارت کا انتشار تین بنیادی حرارتی منتقلی کے طریقوں کے ذریعے ہوتا ہے جو کہ ایک ساتھ کام کرتے ہیں۔ حراست (Conduction) حیطے اور دلی مواد سے گرمی کو خفیہ رابطے کے ذریعے قریبی تیل تک براہ راست منتقل کرتی ہے۔ ٹرانسفارمر کے تیل کی زیادہ حرارتی موصلیت ٹھوس اجزاء سے مائع وسط تک موثر حرارت کی منتقلی کو ممکن بناتی ہے، جو کہ تبرید کے عمل کا پہلا مرحلہ ہے۔

جیسے جیسے گرم تیل ٹرانسفارمر ٹینک میں گردش کرتا ہے، معراج (Convection) حرارت کی منتقلی کا غالب طریقہ بن جاتا ہے۔ یہ سیال حرکت حرارتی توانائی کو اندرونی حرارتی ماخذ سے خارجی تبرید کی سطحوں تک صرف حراست کے مقابلے میں زیادہ مؤثر طریقے سے لے جاتی ہے۔ معراجی حرارت کی منتقلی کا عدد تیل کی بہاؤ کی رفتار، درجہ حرارت کے فرق اور اندرونی اجزاء کی سطح کی خصوصیات پر منحصر ہوتا ہے۔

ریڈی ایشن ٹینک کی خارجی سطحوں سے ماحول میں حرارت کے انتشار میں حصہ ڈالتا ہے۔ ٹینک کی سطح کا رقبہ، اخراج کی خصوصیات، اور ماحولیاتی درجہ حرارت کی حالتیں شعاعی حرارت کی منتقلی کی شرح کو متاثر کرتی ہیں۔ تیار کنندہ اکثر ریڈی ایشن کولنگ کی مؤثریت بڑھانے کے لیے سطح کا رقبہ بڑھانے کے لیے گہرے ہوئے ٹینک کی دیواریں یا خارجی کولنگ فِنز شامل کرتے ہیں۔

تیل کی خصوصیات اور حرارتی انتظام

ٹرانسفارمر تیل کی خصوصیات

ٹرانسفارمر تیل برقی عزل اور حرارت منتقل کرنے کے ذریعہ دونوں کے طور پر دوہرے کام انجام دیتا ہے، جس کے لیے بہترین کارکردگی کے لیے مخصوص جسمانی اور کیمیائی خصوصیات کی ضرورت ہوتی ہے۔ اعلیٰ معیار کے معدنی تیل برقی اجزاء اور زمینی ٹینک ساختوں کے درمیان برقی ٹوٹنے کو روکتے ہوئے بہترین ڈائی الیکٹرک طاقت کا مظاہرہ کرتے ہیں۔ تیل کو معمول کے آپریشن اور ہنگامی لوڈنگ کی حالت کے دوران درپیش وسیع درجہ حرارت کی حدود میں مستحکم عزلی خصوصیات برقرار رکھنی چاہئیں۔

ٹرانسفارمر تیل کی حرارتی خصوصیات سردی کے نظام کی کارکردگی پر نمایاں اثر انداز ہوتی ہیں۔ کم لزوجت قدرتی کنویکشن کے ذریعے تیل کی موثر گردش کو ممکن بناتی ہے، جبکہ زیادہ مخصوص حرارتی صلاحیت تیل کو بہت زیادہ درجہ حرارت میں اضافے کے بغیر شدید حرارتی توانائی جذب کرنے کی اجازت دیتی ہے۔ تیل کی حرارتی موصلیت ٹھوس اجزاء سے گردش کرنے والے سیال تک حرارت منتقل کرنے میں مدد دیتی ہے، جس سے مجموعی طور پر سردی کی مؤثر کارکردگی میں اضافہ ہوتا ہے۔

کیمیائی استحکام یقینی بناتا ہے کہ ٹرانسفارمر تیل طویل مدت تک اپنی خصوصیات برقرار رکھے۔ معیاری تیل آکسیڈیشن، نمی جذب کرنے اور حرارتی تحلیل کا مقابلہ کرتے ہیں جو عزل اور سردی دونوں افعال کو متاثر کر سکتے ہیں۔ باقاعدہ تیل کی جانچ اہم پیرامیٹرز بشمول ڈائی الیکٹرک طاقت، نمی کی مقدار اور تیزابیت کی سطح کی نگرانی کرتی ہے تاکہ مستقل قابل اعتماد آپریشن یقینی بنایا جا سکے۔

تیل کی گردش کے نمونے

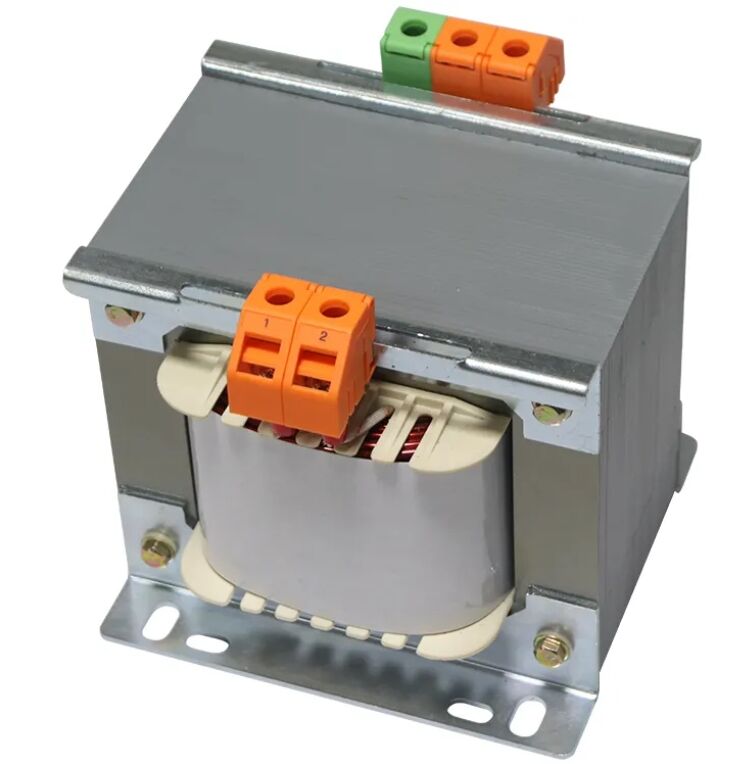

ٹرانسفارمر ٹینک کے اندر موثر تیل کی گردش کے لیے اندرونی اجزاء کی ترتیب اور ٹینک کی جیومیٹری پر غور کرنا ضروری ہوتا ہے۔ تیل میں ڈوبا ہوا ٹرانسفارمر اس ڈیزائن میں تیل کے بہاؤ کے حکمت عملی راستوں کو شامل کیا گیا ہے جو یکساں حرارت کی تقسیم کو فروغ دیتے ہیں اور ان علاقوں سے گریز کرتے ہی ہیں جہاں زیادہ درجہ حرارت پیدا ہو سکتا ہے۔ مناسب گردش یہ یقینی بناتی ہے کہ ٹینک کے اندر تمام اندرونی اجزاء کو ان کی پوزیشن کے باوجود مناسب تعدد ملنے لگے۔

ترانسفارمر ٹینکوں کے اندر گرم تیل کے ابھرنے کے اثرات کی وجہ سے قدرتی طور پر درجہ حرارت کی تہہ بندی ہوتی ہے۔ گرم تیل ٹینک کے اوپری علاقوں میں جمع ہوتا ہے جبکہ ٹھنڈا تیل نچلے حصے کی طرف منتقل ہوتا ہے۔ یہ حرارتی ڈھلان قدرتی کنویکشن کرنسیوں کو حرکت دیتا ہے جو ٹینک کے حجم میں تیل کو گھماتی ہیں۔ انجینئرز قدرتی بہاؤ کے نمونوں سے فائدہ اٹھانے کے لیے وائنڈنگز اور کور اجزاء کی پوزیشن کو بہتر بناتے ہوئے اس گردش کو بہتر بناتے ہیں۔

ساختی حمایتی، ٹیپ چینجرز اور بشرنگ اسمبلیز جیسی اندرونی رکاوٹیں تیل کے بہاؤ کے نمونوں کو متاثر کر سکتی ہیں۔ مناسب ڈیزائن بہاؤ کی حدود کو کم کرتا ہے جبکہ ضروری میکانی حمایت اور برقی کلیئرنس برقرار رکھتا ہے۔ کمپیوٹیشنل فلویڈ ڈائنامکس ماڈلنگ انجینئرز کو تیل کی گردش کے نمونوں کی پیش گوئی کرنے اور زیادہ سے زیادہ تبرید کارآمدی کے لیے اندرونی ترتیبات کو بہتر بنانے میں مدد دیتی ہے۔

بیرونی تبرید کو بہتر بنانے کے طریقے

ریڈی ایٹر سسٹمز

بیرونی ریڈی ایٹرز توانائی حرارت منتقل کرنے کے لیے اضافی سطحی رقبہ فراہم کر کے تیل میں غوطہ زد ٹرانسفارمرز کی حرارت بکھرنے کی صلاحیت کو کافی حد تک بڑھا دیتے ہیں۔ یہ حرارت کے تبادلہ کرنے والے عام طور پر متعدد ٹیوبز یا پینلز پر مشتمل ہوتے ہیں جو گردش کی پائپ لائنز کے ذریعے مرکزی ٹرانسفارمر ٹینک سے جڑے ہوتے ہیں۔ ٹینک کے اوپری علاقے سے گرم تیل ریڈی ایٹر ٹیوبز سے گزرتا ہے جبکہ ٹھنڈا تیل ٹینک کے نچلے حصے میں واپس آ جاتا ہے، جس سے حرارتی بے وزنی کی وجہ سے مسلسل گردش قائم ہوتی ہے۔

ریڈی ایٹر کا ڈیزائن ٹرانسفارمر کی درجہ بندی اور تبرید کی ضروریات کے مطابق مختلف ہوتا ہے۔ چھوٹے ٹرانسفارمر سادہ کرگیٹڈ ٹینک والز یا بولٹ-آن ریڈی ایٹر پینلز کا استعمال کرتے ہیں، جبکہ بڑے یونٹس متعدد تبرید سرکٹس کے ساتھ وسیع ریڈی ایٹر بینکس کی ضرورت ہوتی ہے۔ ریڈی ایٹرز کا سطحی رقبہ اور ترتیب براہ راست ٹرانسفارمر کی لوڈنگ صلاحیت اور آپریٹنگ درجہ حرارت کی حدود کو متاثر کرتا ہے۔

ریڈی ایٹر سطحوں کے اردگرد ماحولیاتی ہوا کا دوران فورسڈ یا قدرتی کنویکشن کے ذریعے تبرید کی مؤثرتا بڑھاتا ہے۔ ہوا کی رفتار، ماحولیاتی درجہ حرارت اور ریڈی ایٹر کی سمت ریڈی ایٹر سطحوں سے اردگرد کی ہوا میں حرارت منتقلی کی شرح کو متاثر کرتی ہے۔ کچھ انسٹالیشنز بجلی کے زیادہ بوجھ یا بلند ماحولیاتی درجہ حرارت کے دوران ہوا کے بہاؤ کو بڑھانے کے لیے فینز یا بلورز شامل کرتے ہیں۔

زور دار ہوا کولنگ

مجبور ہوا کولنگ سسٹمز ٹرانسفارمر کی سطحوں اور خارجی ریڈی ایٹرز کے گرد ہوا کی گردش بڑھانے کے لیے پنکھے یا بلورز کا استعمال کرتے ہیں۔ یہ بہتری کا طریقہ پیک لوڈنگ کے دوران یا ماحولیاتی درجہ حرارت کی حالت میں اضافی کولنگ صلاحیت فراہم کرتا ہے۔ مجبور ہوا کے سسٹمز عام طور پر تیل کے درجہ حرارت یا ٹرانسفارمر لوڈنگ کی سطح کے مطابق خودکار طریقے سے چالو ہوتے ہی ہیں، جب قدرتی طریقے اپنی حد تک پہنچ جاتے ہیں تو کولنگ کو بڑھاوا دیتے ہیں۔

پنکھوں کی ترتیب سادہ سنگل-سپیڈ یونٹس سے لے کر پیچیدہ ویری ایبل-سپیڈ سسٹمز تک مختلف ہوتی ہے جو کولنگ کی ضروریات کے مطابق ہوا کے بہاؤ کو منسلک کرتے ہیں۔ متعدد پنکھے ریڈنڈنسی فراہم کرتے ہیں اور حرارتی حالات کے مطابق مرحلہ وار آپریشن کی اجازت دیتے ہیں۔ مناسب پنکھے کی جگہ ریڈی ایٹر سطحوں پر ہوا کی یکساں تقسیم کو یقینی بناتی ہے جبکہ شور کی سطح اور بجلی کی کھپت کو کم سے کم کرتی ہے۔

کنٹرول سسٹمز ٹرانسفارمر کے درجہ حرارت کی نگرانی کرتے ہیں اور جب معین حد سے تجاوز ہوتا ہے تو خود بخود کولنگ فینز کو چالو کرتے ہیں۔ ان سسٹمز میں ٹرانسفارمر کے مختلف مقامات پر متعدد درجہ حرارت سینسرز شامل ہو سکتے ہیں تاکہ مکمل حرارتی نگرانی یقینی بنائی جا سکے۔ فین کا آپریشن ٹرانسفارمر کی لوڈنگ صلاحیت کو بڑھاتا ہے اور ایمرجنسی کی حالت کے دوران محفوظ آپریٹنگ درجہ حرارت برقرار رکھنے میں مدد دیتا ہے۔

اعلیٰ کولنگ ٹیکنالوجیز

مجبوری تیل کا گردش

بڑے پاور ٹرانسفارمرز میں پمپس کے استعمال سے داخلی تیل کے بہاؤ کو قدرتی کنویکشن کی صلاحیتوں سے بڑھ کر مجبوری تیل کے گردش کے نظام شامل ہو سکتے ہیں۔ یہ سسٹمز تیل کے بہاؤ کی شرح اور گردش کے نمونوں پر بالکل درست کنٹرول فراہم کرتے ہیں، جو زیادہ طاقتور کثافت اور بہتر حرارتی انتظام کو ممکن بناتے ہیں۔ بہت بڑے ٹرانسفارمرز کے لیے پمپ شدہ تیل کا گردش ضروری ہو جاتا ہے جہاں صرف قدرتی کنویکشن کافی کولنگ فراہم نہیں کر سکتی۔

تیل کے پمپ ٹرانسفارمر ٹینک اور خارجی حرارت مبادلہ کنندگان کے اندر مخصوص تبرید سرکٹس کے ذریعے ہدایت شدہ بہاؤ پیدا کرتے ہیں۔ اس جبری گردش سے قدرتی کنویکشن کے ساتھ ہی بننے والے گرم مقامات ختم ہو جاتے ہیں اور ٹرانسفارمر کے پورے وسیع علاقے میں درجہ حرارت کی یکساں تقسیم کو یقینی بنایا جاتا ہے۔ پمپ کی اضافی فراوانی سے یہ یقینی بنایا جاتا ہے کہ خدمت کے دوران اگر الگ الگ پمپ ناکام ہو جائیں تو بھی آپریشن جاری رہے۔

کنٹرول سسٹمز ٹرانسفارمر کے لوڈ اور درجہ حرارت کی حالت کے مطابق پمپ کے آپریشن کو منظم کرتے ہیں۔ متغیر رفتار ڈرائیوز ٹھنڈک کی ضروریات کے مطابق بہاؤ کی شرح میں درست ایڈجسٹمنٹ کی اجازت دیتے ہیں، جس سے توانائی کے استعمال کو بہتر بنایا جا سکے اور مناسب حرارتی انتظام برقرار رکھا جا سکے۔ نگرانی کے نظام پمپ کی کارکردگی کو ٹریک کرتے ہیں اور ممکنہ طور پر درکار مرمت کی ضروریات کے بارے میں ابتدائی انتباہ فراہم کرتے ہیں۔

ہدایت شدہ تیل بہاؤ سسٹمز

ماہرانہ تیل میں لت پت ٹرانسفارمر کے ڈیزائن میں ہدایت شدہ تیل کے بہاؤ کے نظام شامل ہوتے ہیں جو خاص وائنڈنگ کے حصوں اور کور کے علاقوں میں تبريدی تیل کو موڑ دیتے ہی ہیں۔ یہ نظام داخلی نالیاں اور بہاؤ گائیڈز کا استعمال کرتے ہیں تاکہ یقینی بنایا جا سکے کہ اہم اجزاء کو قدرتی کنویکشن کے نمونوں کی پرواہ کیے بغیر مناسب تبريد حاصل ہو۔ ہائی وولٹیج ٹرانسفارمرز میں جہاں وقفے کی پیچیدہ ترتیب ہوتی ہے، ہدایت شدہ بہاؤ خصوصی اہمیت کا حامل ہوتا ہے۔

اندرونی تیل تقسیم کے نظاموں میں سوراخ والے رکاوٹیں، بہاؤ والے چینلز، اور سرکولیشن نالیاں شامل ہو سکتی ہیں جو تیل کی حرکت کو ازقبل طے شدہ راستوں سے گزارنے کی رہنمائی کرتی ہیں۔ اس طریقہ کار سے یقینی بنایا جاتا ہے کہ تمام ٹرانسفارمر اجزاء کو یکساں تبريد فراہم ہو اور درجہ حرارت میں تبدیلی کو کم سے کم کیا جا سکے جو بجلی کی کارکردگی یا اجزاء کی عمر پر اثر انداز ہو سکتی ہے۔ احتیاط سے کیا گیا ڈیزائن وہ بہاؤ کی حدود کو روکتا ہے جو سرکولیشن کی مؤثریت میں رکاوٹ بن سکتی ہیں۔

کئی مقامات پر درجہ حرارت کی نگرانی سے تیل کے بہاؤ کے نظام کی مؤثریت کی تصدیق ہوتی ہے اور آلات کو نقصان پہنچنے سے پہلے ممکنہ گردش کے مسائل کا پتہ چلتا ہے۔ جدید نگرانی کے نظام ٹرانسفارمر کے اجزاء کا حقیقی وقت میں حرارتی نقشہ فراہم کرتے ہیں، جس سے وژن منصوبہ بندی کی حفاظت اور ٹھنڈک کے نظام کی کارکردگی میں بہتری لائی جا سکتی ہے۔

درجہ حرارت کی نگرانی اور کنٹرول سسٹمز

حرارتی سینسرز اور آلہ جات

جدید تیل میں غوطہ زد ٹرانسفارمرز وسیع درجہ حرارت کی نگرانی کے نظام کو شامل کرتے ہیں جو سارے آلات میں اہم مقامات پر حرارتی حالات کی پیروی کرتے ہیں۔ بنیادی درجہ حرارت سینسرز میں اوپری ٹینک کے علاقے میں تیل کے درجہ حرارت کو ناپنے والے انڈیکیٹرز اور ٹرانسفارمر کی وائنڈنگز کے اندر سب سے گرم مقامات کی نگرانی کرنے والے وائنڈنگ درجہ حرارت سینسرز شامل ہیں۔ یہ آلہ آپریشنل کنٹرول اور حفاظتی نظام کے لیے ضروری ڈیٹا فراہم کرتے ہیں۔

موصولگی کے درجہ حرارت کے ڈیٹیکٹرز اور تھرمو کپلز بلند درستگی کے ساتھ درجہ حرارت کی پیمائش فراہم کرتے ہیں اور طویل مدتی استحکام کا اچھا معیار رکھتے ہی ہیں۔ فائبر آپٹک درجہ حرارت کے سینسرز الیکٹرومیگنیٹک تداخل کے خلاف مزاحمت فراہم کرتے ہیں اور چپکے ہوئے مویلنے والے موصلہ کے ساتھ درجہ حرارت کی تقسیم کی نگرانی کی اجازت دیتے ہیں۔ کئی قسم کے سینسرز کو اہم پیمائشوں کے لیے نقل و حمل کے ساتھ جامع حرارتی نگرانی فراہم کرنے کے لیے ملا یا جا سکتا ہے۔

درجہ حرارت کے ڈیٹا حاصل کرنے کے نظام سیںسر کی معلومات کو مقامی نمائش، دور دراز کی نگرانی اور کنٹرول سسٹم کے ان پٹ کے لیے اکٹھا کرتے ہیں اور پرورش کرتے ہیں۔ ڈیجیٹل مواصلاتی پروٹوکول نگرانی کنٹرول سسٹمز اور حالت کی نگرانی کے پلیٹ فارمز کے ساتھ انضمام کو ممکن بناتے ہیں۔ تاریخی درجہ حرارت کے ڈیٹا رجحانات کی نشاندہی کرنے اور ٹرانسفارمر لوڈنگ کی حکمت عملیوں کو بہتر بنانے میں مدد کرتے ہیں اور اہم رہائشی منصوبہ بندی کی معلومات فراہم کرتے ہیں۔

خودکار درجہ حرارت کنٹرول

آٹومیٹک درجہ حرارت کنٹرول سسٹمز ٹرانسفارمر کے حرارتی حالات کو محفوظ آپریٹنگ حدود کے اندر برقرار رکھتے ہیں جس میں کولنگ سسٹم کے آپریشن کو کنٹرول کیا جاتا ہے۔ ان سسٹمز میں عام طور پر متعدد کنٹرول اسٹیجز شامل ہوتی ہیں جو درجہ حرارت بڑھنے کے ساتھ اضافی کولنگ صلاحیت کو فعال کرتی ہیں۔ ابتدائی اسٹیجز کولنگ فینز کو چلانا شروع کر سکتی ہیں، جبکہ زیادہ درجہ حرارت والی سطحوں پر تیل کی سرگرمی کے پمپ یا ایمرجنسی کولنگ سسٹمز کو متحرک کیا جاتا ہے۔

کنٹرول منطق میں مکمل حرارتی حفاظت کو یقینی بنانے کے لیے تیل کے درجہ حرارت اور وائنڈنگ کے درجہ حرارت دونوں ان پٹس کو شامل کیا گیا ہے۔ پروگرام ایبل کنٹرولرز خاص ٹرانسفارمر کی خصوصیات اور آپریٹنگ ضروریات کے مطابق کنٹرول پیرامیٹرز کو حسب ضرورت ڈھالنے کی اجازت دیتے ہیں۔ جدید سسٹمز میں لوڈ شیڈنگ کی صلاحیت بھی شامل ہو سکتی ہے جو اس وقت ٹرانسفارمر کے لوڈ کو کم کر دیتی ہے جب کولنگ سسٹمز محفوظ درجہ حرارت برقرار نہیں رکھ پاتے۔

الارم اور حفاظتی نظام غیر معمولی حرارتی حالات کے بارے میں ابتدائی انتباہ فراہم کرتے ہیں اور ضرورت پڑنے پر حفاظتی اقدامات شروع کرتے ہیں۔ متعدد الارم سطحیں نشوونما پذیر حرارتی مسائل کے لیے درجہ بدرجہ ردعمل کی اجازت دیتی ہیں، صرف انتباہات سے لے کر خودکار طور پر آلات کو بند کرنے تک۔ ہنگامی تبرید کا اطلاق تبرید نظام کی ناکامی یا انتہائی ماحولیاتی حالات کے دوران مستقل کارکردگی کو یقینی بناتا ہے۔

مرمت اور بہتری کی حکمت عملیاں

روک تھام کی دیکھ بھال کی مشقیں

تبرید کے نظام کی باقاعدہ مرمت ٹرانسفارمر کے قابل اعتماد آپریشن کو یقینی بناتی ہے اور آلات کی عمر کو بڑھاتی ہے۔ تیل کے تجزیہ کے پروگرام ٹرانسفارمر کے تیل کی حالت کی نگرانی کرتے ہیں اور ان مسائل کو نشاندہی کرتے ہیں جو تبرید کی کارکردگی کو متاثر کرنے سے پہلے ہی ظاہر ہوتے ہیں۔ اہم پیرامیٹرز میں نمی کی مقدار، ترشی کی سطحیں، حل شدہ گیس کی اقسام، اور ڈائی الیکٹرک طاقت کے پیمانے شامل ہیں جو تیل کی خرابی یا اندرونی مسائل کی نشاندہی کرتے ہیں۔

ریڈی ایٹر اور ہیٹ ایکسچینجر کی صفائی گندگی، ملبہ، اور وہ نباتات کو ہٹا دیتی ہے جو ٹھنڈا کرنے کی مؤثریت کو کم کر دیتی ہیں۔ باقاعدہ معائنہ ہوا کے راستوں کی بندش، خراب شدہ فنس، یا سڑے ہوئے سطحوں کو چھانٹتا ہے جن کی مرمت یا تبدیلی کی ضرورت ہوتی ہے۔ کولنگ فین کی دیکھ بھال میں گریس کرنا، بیلٹ تبدیل کرنا، اور موٹر کے ٹیسٹنگ شامل ہیں تاکہ یقینی بنایا جا سکے کہ جب کولنگ کی اضافی ضرورت ہو تو وہ بھرپور کام کرے۔

درجہ حرارت کی نگرانی نظام کی کیلیبریشن تھرمل سینسرز اور کنٹرول سسٹمز کی درستگی کی تصدیق کرتی ہے۔ خودکار کنٹرول فنکشنز کا باقاعدہ ٹیسٹنگ یقینی بناتا ہے کہ تبدیل ہوتی حرارتی حالات کے مطابق مناسب ردعمل ہو۔ دیکھ بھال کے ریکارڈ سسٹم کی کارکردگی کے رجحانات کو دستاویزی شکل دیتے ہیں اور اس بات کی نشاندہی کرنے میں مدد کرتے ہیں کہ کون سے اجزاء کو ناکامی سے پہلے توجہ کی ضرورت ہوتی ہے۔

پرفارمنس کی بہتری

کولنگ سسٹم کی بہتری میں تھرمل کارکردگی کے ڈیٹا کا تجزیہ کرکے بہتری کے مواقع کی نشاندہی کرنا شامل ہوتا ہے۔ لوڈ فیکٹر کا تجزیہ یہ طے کرنے کے لیے استعمال ہوتا ہے کہ کیا ٹرانسفارمر کی کولنگ صلاحیت حقیقی آپریٹنگ ضروریات کے مطابق ہے۔ تھرمل ماڈلنگ مختلف لوڈنگ کے منظرناموں اور ماحولیاتی حالات کے تحت کارکردگی کی پیشن گوئی میں مدد دیتی ہے۔

ٹرانسفارمر لوڈنگ کی حکمت عملیوں کو بہتر بناتے وقت کولنگ سسٹم کی کارکردگی پر ماحولیاتی درجہ حرارت کے اثرات کو مدنظر رکھنا ضروری ہوتا ہے۔ کولنگ کی موثریت میں موسمی تبدیلیاں زیادہ سے زیادہ محفوظ لوڈنگ کی سطحوں کو متاثر کرتی ہیں اور موسمی آپریٹنگ پیرامیٹرز میں ایڈجسٹمنٹ کی ضرورت ہو سکتی ہے۔ بلندی، نمی اور چلنے والی ہواؤں جیسے مقامی عوامل کولنگ سسٹم کی ڈیزائن کی ضروریات کو متاثر کرتے ہیں۔

سرد کرنے کے نظام میں توانائی کی مؤثریت میں بہتری آپریٹنگ اخراجات کو کم کرتی ہے جبکہ حرارتی کارکردگی برقرار رکھتی ہے۔ ویری ایبل سپیڈ فین ڈرائیوز سرد کرنے کی صلاحیت کو اصل ضروریات کے مطابق یا مقررہ رفتار پر چلانے کے بجائے منضبط کرتے ہیں۔ اسمارٹ کنٹرول سسٹمز حقیقی وقت کی صورتحال اور توقع کردہ لوڈ کے نمونوں کی بنیاد پر سرد کرنے کے نظام کے آپریشن کو بہتر بناتے ہیں۔

فیک کی بات

تیل میں ڈوبے ہوئے ٹرانسفارمرز میں بنیادی سرد کرنے کا طریقہ کار کیا ہے

بنیادی سرد کرنے کا طریقہ کار ٹرانسفارمر کے تیل کے اندر درجہ حرارت کے فرق کی وجہ سے پیدا ہونے والی قدرتی کنویکشن کرنٹس پر منحصر ہوتا ہے۔ بجلی کے نقصانات کی وجہ سے پیدا ہونے والی حرارت تیل کو اوپر اٹھاتی ہے جبکہ ٹھنڈا تیل نیچے کی طرف جاتا ہے، جس سے مسلسل گردش ہوتی ہے جو اندرونی اجزاء سے بیرونی سرد کرنے کی سطحوں تک حرارتی توانائی منتقل کرتی ہے۔ یہ قدرتی گردش کا عمل بیرونی ریڈی ایٹرز کے ذریعے بہتر ہوتا ہے اور بڑے ٹرانسفارمرز میں مجبور ہوا یا تیل کی گردش کے نظام کے ذریعے مدد ملتی ہے۔

ٹرانسفارمر کا تیل سرد کرنے کے عمل میں کیسے حصہ ڈالتا ہے

ٹرانسفارمر تیل حرارتی توانائی کے منتقلی کے ذریعہ اور برقی عزل دونوں کا کام کرتا ہے۔ اس کی مخصوص حرارتی گنجائش اسے نمایاں حرارتی توانائی جذب کرنے کی اجازت دیتی ہے، جبکہ اس کی بہاؤ کی خصوصیات ٹرانسفارمر ٹینک میں موثر سرگرمی کو یقینی بناتی ہیں۔ یہ تیل ونڈنگز اور مرکزی اجزاء سے توانائی کو ترسیل کے ذریعے منتقل کرتا ہے، پھر کنویکشن کے بہاؤ کے ذریعے اس حرارتی توانائی کو ٹھنڈا کرنے والی سطحوں تک لے جاتا ہے۔ معیاری ٹرانسفارمر تیل وسیع درجہ حرارت کی حدود میں مستحکم حرارتی اور برقی خصوصیات برقرار رکھتا ہے۔

تیل میں غوطہ زد ٹرانسفارمرز میں ٹھنڈا کرنے کے نظام کی کارکردگی کو کون سے عوامل متاثر کرتے ہیں

سرد کرنے کے نظام کی مؤثریت پر ماحولیاتی درجہ حرارت، ریڈی ایٹر کی سطح کا رقبہ، تیل کے بہاؤ کے نمونے، اور حرارت منتقل کرنے والی سطحوں کی صفائی جیسے متعدد عوامل کا اثر پڑتا ہے۔ ٹینک کی ڈیزائن اور اندرونی اجزاء کی ترتیب قدرتی کنویکشن کے بہاؤ کو متاثر کرتی ہے، جبکہ ہوا کی حالت اور ریڈی ایٹر کی گندگی جیسے خارجی عوامل حرارت کے ضیاع کی شرح کو متاثر کرتے ہیں۔ سرد کرنے والے پنکھوں کی مناسب دیکھ بھال، صاف ریڈی ایٹر سطحیں، اور معیاری ٹرانسفارمر تیل سب مل کر بہترین حرارتی کارکردگی میں اہم کردار ادا کرتے ہیں۔

تیل میں ڈوبے ہوئے ٹرانسفارمرز کے لیے جبری سرد کرنے کے نظام کب ضروری ہوتے ہیں

جب قدرتی کنویکشن اور ریڈی ایشن معمول یا ہنگامی لوڈنگ کی حالت کے دوران پیدا ہونے والی حرارت کو مناسب طریقے سے منتشر نہیں کر سکتے تو مجبوری تبرید نظام کی ضرورت ہوتی ہے۔ بڑے طاقت کے ٹرانسفارمرز، ایسی یونٹس جو ماحولیاتی بلند درجہ حرارت میں کام کرتی ہیں، یا اعلیٰ لوڈنگ کی ضروریات والے ٹرانسفارمرز کو عام طور پر مجبوری ہوا یا تیل کے گردش کے نظام کی ضرورت ہوتی ہے۔ یہ بہتر تبرید کے طریقے ٹرانسفارمر کی گنجائش کو بڑھاتے ہیں اور مشکل حالات کے دوران محفوظ آپریٹنگ درجہ حرارت کو برقرار رکھتے ہیں جبکہ مختلف لوڈ کی ضروریات کے لیے آپریشنل لچک فراہم کرتے ہیں۔