Urban power distribution networks face unique challenges that require sophisticated electrical equipment designed for safety, efficiency, and environmental compatibility. Modern cities demand power solutions that can operate reliably in confined spaces while minimizing fire risks and environmental impact. A dry transformer represents an innovative approach to electrical distribution that addresses these urban infrastructure needs through advanced insulation technology and compact design principles. These transformers have revolutionized indoor power systems by eliminating the need for liquid coolants while maintaining exceptional performance standards in demanding urban environments.

Understanding Dry Transformer Technology and Construction

Advanced Insulation Systems

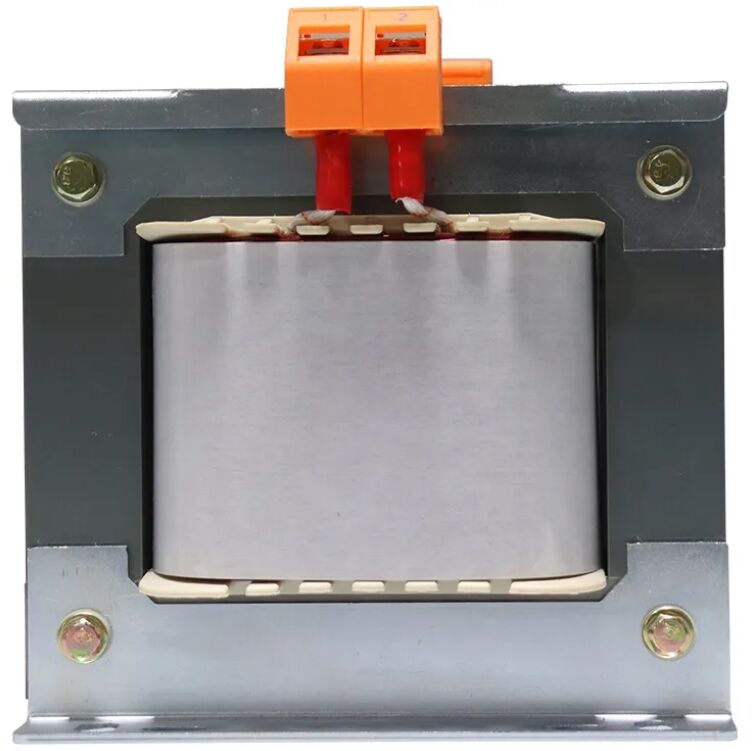

The foundation of dry transformer technology lies in its sophisticated insulation system that replaces traditional liquid coolants with solid materials. These transformers utilize epoxy resin insulation combined with glass fiber reinforcement to create a robust barrier against electrical faults and environmental factors. The insulation system provides superior dielectric strength while maintaining flexibility under thermal cycling conditions. Modern dry transformer designs incorporate vacuum pressure impregnation processes that ensure complete penetration of insulating materials throughout the winding structure.

Temperature class ratings for dry transformers typically range from 130°C to 220°C, allowing operation in various ambient conditions while maintaining long-term reliability. The absence of flammable liquids significantly reduces fire hazards, making these units ideal for installation in occupied buildings and sensitive urban environments. Advanced insulation materials also provide excellent resistance to moisture, dust, and chemical contaminants commonly found in urban settings.

Core and Winding Design Innovations

Contemporary dry transformer construction employs high-grade silicon steel cores with optimized grain orientation to minimize core losses and reduce audible noise levels. The laminated core structure utilizes step-lap joint technology that virtually eliminates air gaps and reduces magnetic flux leakage. Copper or aluminum windings are precision-wound using automated equipment that ensures consistent spacing and optimal heat dissipation characteristics throughout the transformer assembly.

Winding configurations in dry transformer designs often feature cast resin encapsulation that provides mechanical strength and environmental protection. This construction method eliminates the potential for winding movement under fault conditions while providing excellent heat transfer properties. The solid insulation system allows for compact designs with reduced overall dimensions compared to traditional oil-filled units of equivalent capacity.

Safety Advantages in Urban Installations

Fire Safety and Environmental Protection

Urban power installations prioritize fire safety due to the proximity of electrical equipment to occupied spaces and valuable infrastructure. Dry transformer technology eliminates the fire risks associated with flammable coolant fluids, providing inherent safety advantages for indoor applications. The solid insulation materials used in these transformers are self-extinguishing and do not support combustion, significantly reducing the potential for fire propagation in building electrical systems.

Environmental protection benefits extend beyond fire safety to include the elimination of potential coolant spills that could contaminate soil or groundwater. This aspect is particularly important in urban settings where environmental regulations are stringent and cleanup costs can be substantial. The absence of liquid coolants also eliminates the need for containment systems and specialized disposal procedures, simplifying installation and maintenance requirements.

Personnel Safety and Maintenance Access

Maintenance personnel working with dry transformer installations face reduced safety risks compared to liquid-filled alternatives. The absence of pressurized coolant systems eliminates the potential for explosive failures or toxic gas emissions that can occur with certain coolant types. Visual inspection capabilities are enhanced since all major components are accessible without the need to drain coolant fluids or perform complex isolation procedures.

Emergency response procedures are simplified for facilities housing dry transformer equipment, as first responders do not need specialized training for coolant-related hazards. This advantage is particularly valuable in urban environments where rapid emergency response is critical for minimizing service interruptions and protecting public safety.

Performance Benefits for Indoor Applications

Thermal Management and Efficiency

Modern dry transformer designs achieve excellent thermal performance through optimized ventilation systems and advanced materials engineering. Natural convection cooling eliminates the need for auxiliary cooling equipment in most applications, reducing overall system complexity and energy consumption. Forced air cooling options are available for high-capacity installations where space constraints limit natural ventilation effectiveness.

Energy efficiency levels in contemporary dry transformer designs meet or exceed industry standards for comparable liquid-filled units. Low-loss core materials and optimized winding configurations contribute to reduced no-load and load losses, resulting in lower operating costs over the equipment lifecycle. Temperature monitoring systems integrated into modern dry transformer designs provide real-time performance data that enables predictive maintenance strategies and optimal loading practices.

Noise Reduction and Space Optimization

Urban installations often require electrical equipment that operates with minimal audible noise to comply with municipal regulations and maintain comfortable building environments. Dry transformer designs incorporate vibration damping materials and optimized core construction techniques that significantly reduce audible noise levels compared to traditional alternatives. Sound levels typically range from 45 to 65 decibels depending on capacity and installation configuration.

Compact footprints achievable with dry transformer technology enable efficient use of valuable urban real estate. The elimination of coolant expansion tanks, pumping systems, and containment structures allows for installation in smaller spaces while maintaining required clearances for safe operation and maintenance access. This space efficiency is particularly beneficial in high-rise buildings and underground installations where space availability is limited.

Installation and Operational Advantages

Simplified Installation Requirements

Installation procedures for dry transformer systems are significantly streamlined compared to liquid-filled alternatives. The absence of coolant handling requirements eliminates the need for specialized transport equipment and trained personnel for fluid management. Standard rigging equipment can handle dry transformer installations without concerns about coolant spillage or environmental contamination during the installation process.

Foundation requirements are often reduced due to the lighter weight of dry transformer assemblies compared to equivalent liquid-filled units. This weight advantage is particularly beneficial in building installations where structural loading considerations are critical. The compact design also facilitates installation in areas with limited access, such as basement electrical rooms or elevated equipment platforms in urban high-rise buildings.

Reduced Maintenance Requirements

Operational maintenance for dry transformer installations focuses primarily on cleaning and visual inspections rather than complex coolant management procedures. The absence of gaskets, pumps, and fluid handling systems eliminates many potential failure points that require regular maintenance attention. Scheduled maintenance intervals can often be extended compared to liquid-filled alternatives, reducing overall lifecycle costs and service interruptions.

Predictive maintenance technologies integrate effectively with dry transformer designs through temperature monitoring, partial discharge detection, and vibration analysis systems. These monitoring capabilities enable condition-based maintenance strategies that optimize equipment reliability while minimizing unnecessary service interventions. The stable operating characteristics of solid insulation systems provide consistent baseline measurements that enhance the effectiveness of predictive maintenance programs.

Economic Considerations and Lifecycle Value

Initial Investment and Installation Costs

While the initial purchase price of a dry transformer may be higher than comparable liquid-filled alternatives, the total installed cost often favors the dry design due to simplified installation requirements. The elimination of coolant handling, containment systems, and specialized foundation requirements can result in substantial savings during the installation phase. Urban installations particularly benefit from reduced permit requirements and simplified environmental compliance procedures.

Insurance considerations often favor dry transformer installations due to reduced fire risks and environmental liability exposure. Many insurance providers offer reduced premiums for facilities utilizing solid insulation transformer technology, particularly in urban settings where fire protection is a primary concern. These insurance savings can offset higher initial equipment costs over the policy period.

Long-term Operating Economics

Operating cost advantages for dry transformer installations include reduced maintenance expenses, eliminated coolant replacement costs, and simplified disposal procedures at end of service life. The absence of coolant monitoring and treatment requirements eliminates ongoing consumable costs and specialized service contracts. Environmental compliance costs are minimized due to the absence of regulated coolant fluids that require periodic testing and documentation.

Energy efficiency characteristics of modern dry transformer designs contribute to reduced operating costs through lower losses and improved power factor performance. The stable operating characteristics of solid insulation systems maintain consistent efficiency levels throughout the equipment service life, unlike liquid systems that may experience degradation due to coolant contamination or aging.

Applications in Modern Urban Infrastructure

Commercial Building Integration

Modern commercial buildings increasingly specify dry transformer technology for electrical distribution systems due to safety, space, and maintenance advantages. High-rise office buildings benefit from the compact design and reduced fire risks associated with solid insulation transformer technology. The ability to locate dry transformer equipment closer to load centers improves voltage regulation and reduces cable installation costs in large commercial facilities.

Data centers and technology facilities particularly value the reliability and safety characteristics of dry transformer installations. The absence of coolant systems eliminates potential contamination sources that could damage sensitive electronic equipment. Environmental control requirements are simplified since coolant vapors and potential leak detection systems are not necessary for dry transformer installations.

Industrial and Manufacturing Applications

Urban manufacturing facilities often operate under strict environmental regulations that favor dry transformer technology due to elimination of potential coolant spills. Food processing and pharmaceutical manufacturing environments benefit from the absence of potentially contaminating coolant fluids that could affect product quality or regulatory compliance. The robust construction of solid insulation systems provides excellent resistance to industrial contaminants and harsh operating environments.

Process industries utilizing dry transformer technology appreciate the reduced complexity of electrical system maintenance and the elimination of coolant-related downtime. The ability to perform maintenance procedures without coolant drainage significantly reduces service interruption time and associated production losses. Emergency replacement procedures are simplified since dry transformer units do not require coolant conditioning or specialized commissioning procedures.

FAQ

What are the main safety advantages of using dry transformers in urban environments

Dry transformers offer significant safety benefits for urban installations by eliminating fire risks associated with flammable coolant fluids. The solid insulation materials are self-extinguishing and do not support combustion, making them ideal for installation in occupied buildings. Additionally, there are no risks of coolant spills that could contaminate the environment, and maintenance personnel face reduced safety hazards since there are no pressurized fluid systems or toxic vapors to consider.

How do dry transformers compare to oil-filled transformers in terms of maintenance requirements

Dry transformer maintenance is significantly simpler than oil-filled alternatives since there are no coolant fluids to monitor, test, or replace. Maintenance procedures focus primarily on cleaning and visual inspections rather than complex fluid management tasks. The absence of gaskets, pumps, and coolant handling systems eliminates many potential failure points, often allowing for extended maintenance intervals and reduced lifecycle costs.

Are dry transformers suitable for high-capacity power distribution applications

Modern dry transformer technology is available in a wide range of capacities suitable for most urban power distribution needs. While traditionally limited to smaller capacities, current designs can handle substantial loads while maintaining excellent efficiency and reliability characteristics. For extremely high-capacity applications, multiple dry transformer units can be paralleled to achieve the required total capacity while maintaining the safety and operational advantages of solid insulation technology.

What factors should be considered when selecting between dry and liquid-filled transformers for indoor installations

The selection between dry and liquid-filled transformers for indoor applications should consider fire safety requirements, available installation space, maintenance capabilities, and local environmental regulations. Dry transformers are typically preferred for applications where fire safety is paramount, space is limited, or where simplified maintenance procedures are desired. The total cost of ownership, including installation, operation, and maintenance expenses, should be evaluated alongside the specific safety and performance requirements of the installation.

Table of Contents

- Understanding Dry Transformer Technology and Construction

- Safety Advantages in Urban Installations

- Performance Benefits for Indoor Applications

- Installation and Operational Advantages

- Economic Considerations and Lifecycle Value

- Applications in Modern Urban Infrastructure

-

FAQ

- What are the main safety advantages of using dry transformers in urban environments

- How do dry transformers compare to oil-filled transformers in terms of maintenance requirements

- Are dry transformers suitable for high-capacity power distribution applications

- What factors should be considered when selecting between dry and liquid-filled transformers for indoor installations