Introduction to Oil-Immersed and Dry-Type Transformers

Core Definitions and Basic Functions

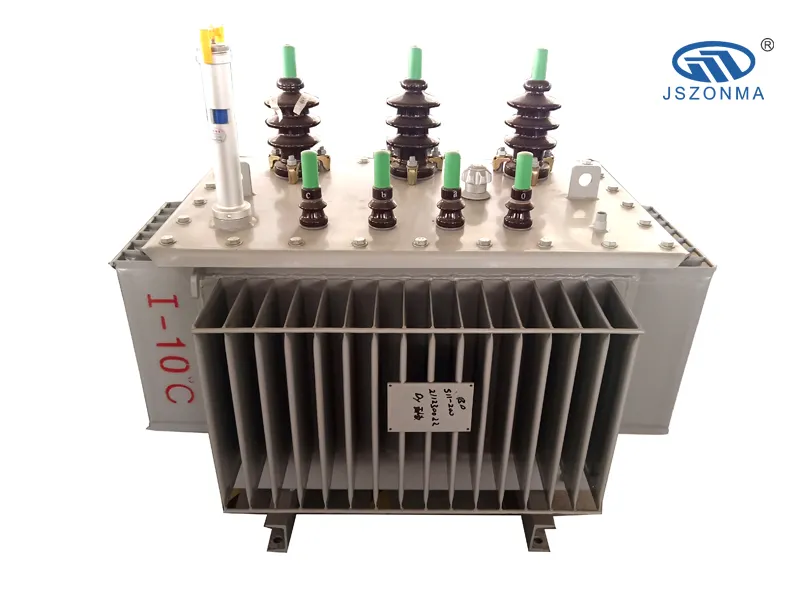

When it comes to electrical power systems, oil immersed transformers and dry type transformers play really important roles, though they look quite different from one another and work best in certain situations. Oil immersed ones, sometimes called liquid filled transformers, rely on oil both to keep things cool and act as insulation. Dry type models instead depend on air or gases for cooling and insulation, which is why they tend to be better choices for inside buildings. These devices basically do the same job across our power grids transforming voltages so that electricity can be used properly wherever needed. We typically see oil immersed transformers out in rural areas or far away locations because they handle high voltage loads pretty well and last longer under tough conditions. Meanwhile, cities and towns mostly go with dry type transformers since people care more about safety issues and what impact these units might have on the environment around them.

Historical Roles in Power Distribution Systems

Since they first appeared back in the late 1800s, transformers have played a major role in how we distribute electricity across our power grids. Back when the industry started, most transformers were filled with oil, but over time things changed as companies began moving toward dry type models because people cared more about safety issues and what kind of impact these devices had on the environment. There were some key moments in this shift too. Think about those big electrical projects where engineers realized just how dangerous traditional transformers could be under certain conditions. As technology keeps advancing and our demand for cleaner energy grows, we're seeing continuous improvements in transformer design. What's happening now isn't just changing how grids operate today, it's actually setting the stage for all sorts of new possibilities in transformer tech down the road.

Design and Construction: Key Differences

Cooling Mechanisms: Oil Immersion vs. Air/Resin

Oil immersed transformers depend on transformer oil for cooling since it conducts heat away from internal parts pretty well. This helps keep things running smoothly without getting too hot. Dry type transformers work differently though. They either use just air circulation or some kind of resin material for cooling purposes. But honestly, these alternatives don't move heat around as effectively as oil does, which means they can struggle when temperatures rise. Research from IEEE Transactions on Power Delivery looked into how these different cooling approaches perform, finding that oil based systems generally handle heat better than their counterparts. Because of this difference in cooling capacity, we actually see variations in how long these transformers last and how efficiently they operate under normal conditions.

Insulation Materials and Thermal Management

When it comes to insulation in transformers, oil and resin offer quite different characteristics suited for various thermal management requirements. Transformers filled with oil take advantage of oil's insulating qualities, which help manage heat really well and actually extend how long they last because the oil carries away excess warmth efficiently. Dry type transformers work differently though. They mostly depend on either resin or just plain air for insulation. While their insulation isn't quite as good as what oil provides, there's a big plus side here safety wise since they pose much less risk when it comes to catching fire. Most industries follow guidelines set out by organizations like the International Electrotechnical Commission (IEC) regarding these materials. These standards basically create a common framework so manufacturers know exactly what kind of performance to expect no matter where their equipment ends up being used.

Physical Build: Tank-Based vs. Encapsulated Designs

The way transformers are built matters a lot when it comes to performance. Oil immersed transformers have long been constructed using tanks filled with oil that submerges all the internal parts. This setup saves space, which explains why they work so well in places where going vertical makes sense for installation. On the other hand, dry type transformers typically come with encapsulated builds. These tend to fit better in tight spaces found throughout cities. Because of how they're made, oil immersed units really shine in big rural power stations needing lots of capacity. Meanwhile, dry types become the go to choice in urban areas where safety standards matter more and there just isn't room for bulky equipment. Most engineers will tell you this distinction between construction methods determines where each transformer type finds its sweet spot in real world applications.

Performance Metrics: Efficiency and Operational Capabilities

Load Capacity and Voltage Handling Comparisons

Looking at oil immersed versus dry type transformers reveals some key differences when it comes to how much load they can carry. Oil immersed models generally handle bigger loads thanks to their design that uses oil to get rid of heat efficiently. Because of this, they work well in places with lots of demand like factories or big power stations. Dry type transformers tend to have lower capacity limits, so they're better suited for inside spaces where safety matters most and there's concern about possible leaks or fires. For dealing with voltage spikes, oil immersed transformers perform better during peak times since the oil acts as insulation against electrical breakdowns. Dry types aren't quite as good here because they depend on air cooling, which isn't as effective when things get really hot. Industry experience shows these oil based units maintain stability even when pushed hard, something many facilities need for reliable operation.

Energy Losses: No-Load vs. Load Scenarios

Transformer energy losses really matter for how efficiently systems run and what gets spent on maintenance. Oil immersed and dry type transformers both suffer from these losses, though they happen in different ways depending if the transformer is running or just sitting idle. When transformers sit without any load, oil immersed models typically lose more power since the core needs constant magnetization. But once loaded up, oil does wonders for cooling, cutting down those pesky resistive losses. Dry type transformers tell a different story. They generally waste less power when idle thanks to not having all that extra oil weight around. Still, problems pop up when they're actually working hard because air or resin cooling just isn't as good as liquid cooling. Real world data shows that picking one transformer over another makes a big difference in energy bills and overall system performance, especially after years of operation.

Lifespan and Long-Term Reliability Benchmarks

How long transformers last and how reliable they are really comes down to what they're built with and how they're made. Oil immersed models tend to stick around longer because the oil helps keep things cool and protects internal parts over time. Dry type transformers do have their advantages though, especially when it comes to being safer and better for the environment. But these often don't last as long since air or resin insulation just can't handle extreme temperatures as well. Tests and field data consistently point to oil immersed units performing better in different weather conditions. The oil serves dual purposes acting as both cooling agent and electrical barrier against sudden heat changes. Dry types struggle more in places with high humidity or dust buildup where their air based protection isn't enough. What most engineers find through experience is that picking between these transformer types boils down to where they'll be installed and what kind of work they need to do day to day. Getting this choice right makes all the difference in equipment lifespan and keeping operations running smoothly without unexpected failures.

Safety Profiles and Maintenance Requirements

Fire Risks: Flammable Oil vs. Non-Combustible Materials

Oil immersed transformers present real fire risks because they contain flammable substances like mineral oil used for cooling purposes. When these transformers run at high loads, there's a greater chance of overheating that can trigger dangerous situations. That's why many facilities avoid installing them in areas where fire safety matters most. Dry type transformers tell a different story though. They're built with materials that won't catch fire easily, making them much safer alternatives. Since they don't have any liquid components inside, there's simply less material available to burn. Industry standards organizations rate dry types higher on safety scales precisely because of this design feature. Most electricians will recommend dry types for spaces like server rooms, hospitals, or other locations where even small fires could cause major problems. The contrast between these two transformer types definitely plays a big role when deciding what kind of equipment goes into critical infrastructure projects.

Maintenance Routines: Oil Testing vs. Minimal Servicing

Maintaining oil immersed transformers usually involves pretty detailed work focusing on regular oil tests. The transformer oil does double duty as both cooling system and insulation material, so technicians need to check it often for things like dirt buildup or chemical breakdowns, plus replace it every so often when needed. All this takes special tools and trained personnel, which adds up to bigger maintenance bills month after month. Dry type transformers tell a different story altogether when it comes to upkeep costs. Their solid state construction means there's no liquid to worry about, and far fewer parts that can break down over time. Most facilities find they don't need to schedule inspections as frequently either. Real world data from manufacturing plants shows maintenance budgets drop by around 40% when switching to dry types. For operations running in moderate conditions where extreme temperatures aren't common, these transformers offer real money saving potential without sacrificing performance.

Environmental Impact and Disposal Challenges

Using oil immersed transformers comes with environmental risks mainly because spilled oil can contaminate soil and water sources. This means companies need good containment systems and regular checks to stop ecological problems from happening. Dry type transformers solve this issue since they don't contain oil at all, so there's less chance of environmental harm and they're generally easier to get rid of when they reach the end of their life. Still, both kinds of transformers present disposal headaches governed by various regulations about how they should be handled after service. With oil immersed units, local laws typically demand proper disposal methods for old oil and make sure old equipment doesn't become a pollution source. Dry type transformers might be simpler to dispose of overall, though they still need to follow certain environmental rules during dismantling. Looking at actual cases shows why sticking to these regulations matters so much for reducing environmental impact and keeping our approach to electrical component disposal as green as possible.

Cost Considerations and Application Suitability

Initial Investment and Installation Cost Analysis

Looking at upfront costs, oil immersed transformers tend to be cheaper than dry type models most of the time. Partly because they're so common on the market and easier to install too. But there are plenty of things that can throw off these numbers. Where the project is located matters a lot, what kind of specs we need for those transformers, plus how much labor will actually cost in practice. Take remote sites for example - getting equipment there adds all sorts of extra fees that really eat into budgets. From what manufacturers see across the industry, dry type transformers usually come with bigger price tags since they need special parts and skilled workers to handle them properly. Still worth considering though if companies want to save money later on through lower maintenance needs and better running efficiency over time.

Operational Expenses Over Time

Looking at operating costs really shows the difference between oil immersed and dry type transformers over time. Transformers filled with oil generally need more regular upkeep work like checking the oil quality and replacing it when needed, something that adds up month after month. Dry type models usually cost less to maintain because they're built tougher and don't need those same kinds of checks so often. Many factories have found through years of running both types that even though dry transformers cost more upfront, they actually save money in the long run. This matters a lot for facilities trying to cut down on maintenance downtime and meet green energy goals too.

Ideal Use Cases: Industrial Complexes vs. Urban Grids

Choosing the right kind of transformer really depends on what it needs to do. Oil immersed transformers work best in big industrial places that need reliable power at high voltages. These transformers can take all sorts of load changes without breaking a sweat, which is why factories and manufacturing plants stick with them for their heavy duty operations. On the flip side, dry type transformers shine when there's limited space and safety matters most. They fit nicely into tight spots without the fire hazards associated with oil, so we see them everywhere from office buildings to subway tunnels and even near nature preserves where environmental impact counts. Look around any city with green energy initiatives and chances are good someone installed dry type transformers somewhere. Cities like New York and Tokyo have rolled out these transformers across their solar panel networks because they just make sense for crowded urban landscapes.

FAQ

What is the primary difference between oil-immersed and dry-type transformers?

Oil-immersed transformers use oil for cooling and insulation, while dry-type transformers use air or resin, typically suited for indoor environments.

Why are dry-type transformers preferred in urban settings?

Dry-type transformers offer enhanced safety and reduced fire risk due to their non-combustible materials, making them ideal for confined and urban environments.

Which type of transformer is more cost-effective in terms of maintenance?

Dry-type transformers are generally more cost-effective in maintenance due to their minimal servicing requirements and non-fluid design.

How do oil-immersed transformers impact the environment?

Oil-immersed transformers pose spill risks that can lead to soil and water contamination, requiring robust containment measures.

Are oil-immersed transformers suitable for high-voltage applications?

Yes, oil-immersed transformers are ideal for high-voltage applications due to their superior load handling and cooling capabilities.

Table of Contents

- Introduction to Oil-Immersed and Dry-Type Transformers

- Design and Construction: Key Differences

- Performance Metrics: Efficiency and Operational Capabilities

- Safety Profiles and Maintenance Requirements

- Cost Considerations and Application Suitability

-

FAQ

- What is the primary difference between oil-immersed and dry-type transformers?

- Why are dry-type transformers preferred in urban settings?

- Which type of transformer is more cost-effective in terms of maintenance?

- How do oil-immersed transformers impact the environment?

- Are oil-immersed transformers suitable for high-voltage applications?