جیانگسو یونیٹا الیکٹرک ایکویپمنٹ کمپنی لمیٹڈ کی جانب سے تیار کردہ مکمل طور پر سیل شدہ تیل میں لتھڑتا ہوا بجلی کے ٹرانسفارمر کا کم نقصان، کم شور اور زیادہ کارآمدی کا فائدہ ہے جو اچھے توانائی بچت کے اثر کو حاصل کر سکتا ہے اور آلودگی کو کم کر سکتا ہے۔

عمومی تیل سے بھرے ٹرانسفارمر کے مقابلے میں، مکمل سیل شدہ ٹرانسفارمر آئل کنسرویٹر کو ختم کر دیتا ہے، اور تیل کے حجم کی تبدیلی کو خود بخود ایڈجسٹ اور کمپنیٹ کیا جاتا ہے، جو کریسنٹڈ ٹینک کی شیٹ کی لچک کے ذریعے ہوتا ہے۔

ٹرانسفارمر ہوا سے الگ کر دیا جاتا ہے، اس طرح تیل کی خرابی اور ان سولیشن کی عمر کو روکنے اور سست کرنے میں مدد ملتی ہے، آپریشن کی قابل اعتمادیت بڑھ جاتی ہے، اور معمول کے آپریشن میں دیکھ بھال سے گریز کیا جاتا ہے۔

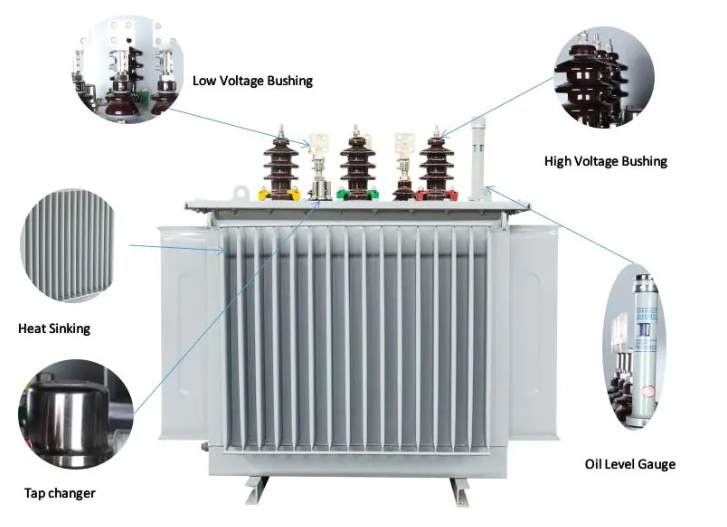

ٹرانسفارمر کے بنیادی اجزاء:

اس ٹرانسفارمر کے بنیادی حصوں میں تیل کا ٹینک، کنسرویٹر، بوچہولز ریلے، براشر یونٹ، تیل اشاریہ، درجہ حرارت کا پتہ لگانے والا آلہ، دباؤ کو کم کرنے والا آلہ، تھرمل ریلے، ریڈی ایٹر، اور بوشسنگ شامل ہیں۔

1.تیل ٹینک کا استعمال ونڈنگز کو بھگونے کے لیے کیا جاتا ہے اس میں رکھ کر۔

2.لوڈنگ کے دوران آسانی سے رابطہ کیا جا سکے اور پھیل جائے تاکہ تیل کا درجہ حرارت بڑھایا اور کم کیا جا سکے۔

3. جب کنسرویٹر ٹینک کا استعمال کیا جاتا ہے تو بوچولز ریلے کا استعمال کیا جاتا ہے۔ کیونکہ جب تیل کم ہو جاتا ہے تو یہ خامیوں جیسے تیل کے ضائع ہونے، ٹینک اور ٹرانسفارمر کے درمیان تیل کے غیر مناسب بہاؤ کو ظاہر کرتا ہے۔

4.بریتھر یونٹ میں سلیکا جیل شامل ہوتا ہے جو تیل میں نمی کو جذب کرتا ہے۔ یہ اپنا رنگ نیلے رنگ سے گُلابی رنگ میں تبدیل کر دیتا ہے جب یہ تیل میں نمی کو جذب کرنے کی صلاحیت سے محروم ہو جاتا ہے۔

5. تیل انڈیکیٹر کنسرویٹری یونٹ کے اندر تیل کی سطح کو ظاہر کرتا ہے۔

6. درجہ حرارت کا پتہ لگانے والا آلہ تیل کے درجہ حرارت کی نگرانی کرتا ہے۔ اگر تیل کا درجہ حرارت ایک مخصوص سطح تک بڑھ جاتا ہے تو ٹرانسفارمر کو سروس سے الگ کر دیا جائے گا۔

7.دباو کم کرنے والا آلہ ٹرانسفارمر کے اندر دباو کو کم کرتا ہے تاکہ ٹرانسفارمر کے دھماکے سے بچا جا سکے۔

8. تھرمل ریلے کا استعمال ونڈنگ کے درجہ حرارت کے اشاریے کے طور پر کیا جاتا ہے

9. بوشِنگ کا استعمال ٹرانسفارمر کے اندر کے وائنڈنگز کو ایک برقی نیٹ ورک کی مدد سے جوڑنے کے لیے کیا جاتا ہے۔