Jiangsu Unita Electric Equipment Co., Ltd. မှ ထုတ်လုပ်သော အပြည့်အ၀ အလုံပိတ် ဆီနှစ်မြှုပ်ပါဝါ ထရန်စဖော်မာတွင် ပါ၀င်ပါသည်။ low loss, low noise and high efficiency ၏အားသာချက် ကောင်းမွန်တဲ့ စွမ်းအင်ချွေတာတဲ့ အကျိုးသက်ရောက်မှုကို ရရှိစေပြီး ညစ်ညမ်းမှုကို လျှော့ချပေးနိုင်ပါတယ်။

သာမာန်ဆီနှစ်မြှုပ်ထားသော ထရန်စဖော်မာနှင့် နှိုင်းယှဉ်ပါက အပြည့်အလုံပိတ်ထရန်စဖော်မာသည် ဆီကွန်ဆာဗေးတစ်ကို ဖျက်သိမ်းပေးကာ ဆီပမာဏပြောင်းလဲမှုကို ဆီတိုင်ကီ၏ ကော်ရူဂတ်စာရွက်၏ elasticity ဖြင့် အလိုအလျောက်ချိန်ညှိကာ လျော်ကြေးပေးပါသည်။

ထရန်စဖော်မာသည် လေနှင့်အထီးကျန်ဖြစ်ပြီး ဆီယိုယွင်းခြင်းနှင့် လျှပ်ကာများ အိုမင်းရင့်ရော်မှုကို တားဆီးရန်နှင့် နှေးကွေးစေရန်၊ လည်ပတ်မှုယုံကြည်စိတ်ချရမှုကို မြှင့်တင်ရန်နှင့် ပုံမှန်လည်ပတ်မှုတွင် ပြုပြင်ထိန်းသိမ်းမှုကို ရှောင်ကြဉ်ရန်။

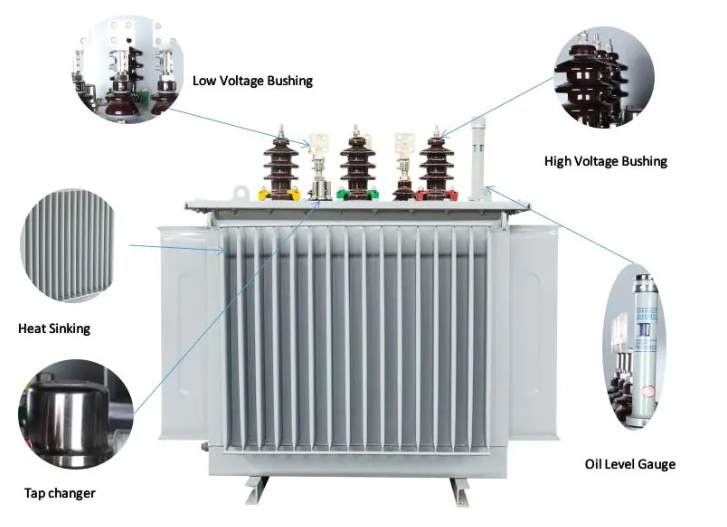

ထရန်စဖော်မာ၏ အဓိက အစိတ်အပိုင်းများ-

ထရန်စဖော်မာ၏ အဓိက အစိတ်အပိုင်းများတွင် ဆီတိုက်၊ သိမ်းဆည်းရေးအိုင်း၊ ဘူချိုလ်ဇ် ရီလေး၊ ရေနွေးစီးစနစ်၊ ဆီညွှန်ပြသည့်ကိရိယာ၊ အပူချိန် တိုင်းတာသည့်ကိရိယာ၊ ဖိအား လွတ်လပ်စေရေး ကိရိယာ၊ အပူချိန် ရီလေး၊ အပူလျှပ်စစ်ပြား၊ နှင့် ဘူရှင်းတို့ ပါဝင်ပါသည်။

1.အိုင်လ်တင်ကိုင်သည် လှိုင်းများကို ထိုင်သွင်းရန်အတွက် အသုံးပြုသည်။

2.ဆက်သွယ်ရန် လွယ်ကူပြီး တင်သွင်းစဉ်ကာလအတိုင်း ကျယ်ပြန့်လာမည်ဖြစ်ပါက ဆီ၏ အပူချိန် မြင့်တက်ခြင်းနှင့် လျော့နည်းခြင်းဖြစ်မည်ဖြစ်သည်။

3. Buchholz relay သည် conservator tank ကိုအသုံးပြုသောအခါအသုံးပြုသည်။ အဲဒီတော့ လျှော့ချမှုရှိသောအခါ ဆေးထုပစ္စည်းကိုဆုံးဖြတ်ပေးသည်၊ ဆေးထု၏မူလလှုပ်ရှားမှုများကိုတိုင်းတာသည်။

4.Breather Unit သည် ဆေးထုထဲရှိ ရေအား ယူဆပေးသည့် silica gel ကိုပါဝင်သည်။ အဲဒီအရာက blue color မှ pink color သို့ပြောင်းလိုက်သည်ဆိုရင် ဆေးထုထဲရှိ ရေကို ယူဆနိုင်မှုမရှိပါ။

5. ဆေးထုညွှန်ကြားသည် conservatory unit ထဲရှိ ဆေးထုအဆင့်ကိုညွှန်ကြားသည်။

6. အိုင်လ်၏အပူချိန်ကိုတိုင်းတာသည့် temperature detector သည် အပူချိန်အဆင့်တစ်ခုသို့ရောက်လာသည်ဆိုရင် တရားဖြေသည်ကို service မှချုပ်ထုတ်ပေးသည်။

7.Pressure relief device သည် transformer ၏အတွင်းရှိအားကိုလျှော့ချရန်အတွက် သို့မဟုတ် transformer ၏ရောင်းချခြင်းကိုရှောင်ရှားရန်အတွက်အသုံးပြုသည်။

8. Thermal relay သည် winding ၏အပူချိန်အတွက် indicator အဖြစ်အသုံးပြုသည်။

9. The bushing သည် transformer ၏အတွင်းရှိ winding ကို exterior electrical network နှင့်ဆက်သွယ်ရန်အသုံးပြုသည်။