Riktig vedlikehold av elektrisk infrastruktur er fortsatt avgjørende for industrielle operasjoner, der oljetransformatorer fungerer som bærende komponenter i kraftforsyningssystemer verden over. Disse essensielle enhetene krever systematisk omsorg for å sikre optimal ytelse, utvide driftslevetiden og forhindre kostbare feil som kan forstyrre hele anlegg. Forståelse av omfattende vedlikeholdsprotokoller blir stadig viktigere ettersom bedrifter er sterkt avhengige av uavbrutt strømforsyning for sine operasjoner.

Moderne industrielle anlegg er avhengige av pålitelige kraftforsyningssystemer som kan håndtere varierende elektriske belastninger samtidig som de opprettholder konstante spenningsnivåer. Oljetransformatorer spiller en sentral rolle i denne prosessen ved å skalerer spenningen opp eller ned etter behov gjennom det elektriske nettverket. Disse sofistikerte enhetene bruker mineralolje både som isolerende medium og kjølemiddel, noe som gjør riktig oljehåndtering til en grunnleggende del av effektive vedlikeholdsstrategier.

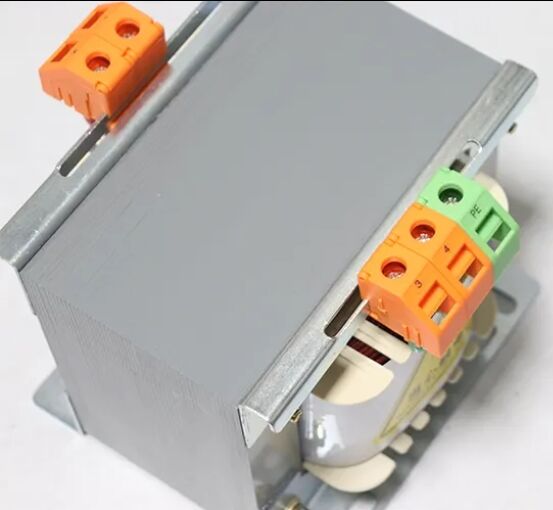

Kompleksiteten til oljetransformatorsystemer krever at vedlikeholdsprofesjonelle forstår flere sammenknyttede komponenter, inkludert viklinger, tappebrytere, isolatorer og beskyttelsesreleer. Hver enkelt komponent bidrar til systemets totale pålitelighet, og å overse noen av elementene kan kompromittere hele enhetens ytelse. Regelmessige vedlikeholdsprosedyrer hjelper til med å identifisere potensielle problemer før de eskalerer til større problemer som kan føre til utstyrssvikt eller sikkerhetsrisiko.

Vedlikehold av oljeanalyse og testprosedyrer

Grunnleggende oppløst gassanalyse

Analyse av oppløst gass representerer ett av de viktigste diagnostiske verktøyene for vedlikehold av oljetransformatorer, og gir tidlige advarsler om interne feil før de utvikler seg til katastrofale svikt. Denne testmetoden analyserer gasser oppløst i transformatoreolje for å identifisere spesifikke feiltilstander som overoppheting, lysbue eller isolasjonsnedbrytning. Fagmiljøer innen vedlikehold samler regelmessig oljeprøver og sender dem til akkrediterte laboratorier for omfattende analyse.

Tolkning av resultater fra analyse av oppløst gass krever spesialisert kunnskap om gassdanningsmønstre og deres tilhørende feilmekanismer. Hydrogen, metan, etan, etylen, acetylen, karbonmonoksid og karbondioksid indikerer hver for seg ulike typer interne problemer når de forekommer i unormale konsentrasjoner. Å forstå disse sammenhengene gjør at vedlikeholdsansvarlige kan prioritere reparasjoner og planlegge nedetid effektivt.

Opprettelse av grunnleggende målinger for nyinstallerte oljetransformatorer gir verdifulle referansepunkter for fremtidige sammenligninger. Regelmessige testintervaller, vanligvis hvert sjette til tolvte måned avhengig av enhetens kritikalitet og driftsforhold, hjelper på å følge endringer i oljekvaliteten over tid. Disse historiske dataene er svært verdifulle for å forutsi vedlikeholdsbehov og optimalisere utskiftningsskjema.

Metoder for vurdering av oljekvalitet

Fysiske og kjemiske egenskaper ved transformatorolje påvirker utstyrets isolasjonsevne og varmeoverføringseffektivitet direkte. Viktige parametere inkluderer dielektrisk styrke, fuktkonsentrasjon, surhetsgrad, grenseflatepenning og effektfaktormålinger. Disse egenskapene bestemmer samlet sett om oljen fortsatt kan gi tilstrekkelig beskyttelse for interne komponenter, eller om den må behandles eller skiftes ut.

Dielektrisk styrketesting måler oljens evne til å motstå elektrisk påkjenning uten å bryte sammen, hvor minimumsverdier vanligvis er spesifisert av utstyrproducenter og bransjestandarder. Analyse av fuktkontaminering avdekker vannnivåer som kan betydelig redusere isolasjonsevnen og fremme korrosjon av metalliske deler. Regelmessig overvåking av disse parametrene hjelper vedlikeholdslag med å ta informerte beslutninger omkring krav til oljeprosessering.

Avanserte oljetestmetoder, som furananalyse, gir innsikt i celluloseisolasjonsnedbrytning i transformatorviklinger. Denne testmetoden oppdager furanforbindelser som dannes når papirisolasjonen alder, og gir verdifull informasjon om den resterende levetiden til kritiske isolasjonssystemer. I kombinasjon med andre oljeanalyseresultater muliggjør furantesting en mer nøyaktig vurdering av den totale transformatortilstanden.

Omfattende inspeksjons- og overvåkningsstrategier

Eksterne visuelle inspeksjonsprotokoller

Systematiske eksterne inspeksjoner utgjør grunnlaget for effektive vedlikeholdsprogrammer for oljetransformatorer og gjør det mulig å oppdage synlige problemer i et tidlig stadium, noe som kan indikere interne feil. Inspeksjonene bør omfatte alle tilgjengelige komponenter, inkludert tanken, isolatorer, kjølesystemer, beskyttelsesutstyr og tilhørende elektriske tilkoblinger. Dokumentasjon av inspeksjonsfunn skaper verdifulle vedlikeholdsdokumenter og bidrar til å følge utviklingen av utstyrets tilstand over tid.

Termografiske undersøkelser utført under rutineinspeksjoner kan avsløre varmeområder som kan indikere løse forbindelser, overbelasted komponenter eller problemer med kjølesystemet. Disse ikke-invasive diagnostiske metodene gjør at vedlikeholdslag kan identifisere potensielle problemer uten å ta utstyret ut av drift. Regelmessige termografiske undersøkelser bør planlegges i perioder med maksimal belastning for å maksimere effektiviteten av temperaturbasert diagnostikk.

Oljenivåovervåkning krever nøye oppmerksomhet på målerlesninger og hensyntakelse til omgivelsestemperaturvirkninger som kan forårsake normal utvidelse og krymping. Uforklarte endringer i oljenivå kan indikere lekkasjer, akkumulering av intern gass, eller andre problemer som krever umiddelbar etterforskning. Vedlikehold av riktig oljenivå sikrer tilstrekkelig kjøling og isolasjon, samtidig som det forhindrer at interne komponenter utsettes for luft og fuktighet.

Teknikker for vurdering av interne komponenter

Interne inspeksjoner av oljetransformator komponenter krever spesialiserte prosedyrer og sikkerhetsprotokoller på grunn av tilstedeværelse av strømførende utstyr og potensielt farlige materialer. Disse omfattende undersøkelsene skjer vanligvis under planlagte vedlikeholdsstans og gir mulighet til å vurdere tilstanden til viklinger, tappebryterdrift og interne tilkoblinger som ikke kan vurderes under normal drift.

Kjerne- og viklingsinspeksjoner innebærer omhyggelig visuell undersøkelse for tegn på overoppheting, mekanisk skade eller isolasjonsnedbrytning. Deteksjon av fuktighet i transformertanker krever umiddelbar oppmerksomhet, da vannkontaminering raskt kan nedbryte isolasjonssystemer og skape forhold som fremmer interne feil. Faglige vedlikeholdslag bruker spesialisert utstyr for å måle fuktnivåer og iverksetter passende tørkeprosedyrer når det er nødvendig.

Vurdering av bushings tilstand fokuserer på porselens integritet, tetningspakningers tetthet og interne lederforbindelser som med tiden kan utvikle problemer på grunn av termisk syklus og mekanisk spenning. Disse kritiske komponentene gir grensesnittet mellom interne viklinger og eksterne elektriske systemer, noe som gjør deres korrekte vedlikehold avgjørende for helhetlig systempålitelighet. Regelmessig inspeksjon og testing av bushinger bidrar til å forhindre feil som kan skade både transformatoren og tilknyttet utstyr.

Preventiv Vedlikeholdsplanlegging og Gjennomføring

Planlagte vedlikeholdsintervaller

Å etablere passende vedlikeholdsintervaller for oljetransformatorer krever nøye vurdering av driftsforhold, produsentanbefalinger og regulatoriske krav. Enheter med høy kritikalitet som betjener vesentlige laster, kan kreve hyppigere oppmerksomhet enn reservetransformatorer med lavere utnyttelsesfaktor. Miljøfaktorer som ekstreme temperaturer, fuktighet og forurensningsnivåer påvirker også optimalt vedlikeleggingsprogram.

Å koordinere vedlikeholdsarbeid med anleggets drift bidrar til å minimere forstyrrelser samtidig som det sikrer tilstrekkelig tid til grundige inspeksjoner og reparasjoner. Avansert planlegging gjør det mulig å anskaffe nødvendige reservedeler, planlegge inn spesialiserte entreprenører og ordne midlertidige strømkilder når det er påkrevd. Effektiv vedlikeholdsplanlegging balanserer behovet for utstyrets pålitelighet mot operative begrensninger og budsjetthensyn.

Dokumentasjon av vedlikeholdsaktiviteter skaper verdifulle historiske oppføringer som støtter garantiuttalelser, regelverksmessig etterlevelse og fremtidige planleggingsbeslutninger. Detaljerte vedlikeholdslogger bør inkludere inspeksjonsfunn, testresultater, reparasjons tiltak og informasjon om utskiftede deler. Denne omfattende dokumentasjonen muliggjør trendanalyse og bidrar til å optimere fremtidige vedlikeholdsstrategier basert på faktiske data om utstyrets ytelse.

Proaktiv utskifting av komponenter

Strategisk utskifting av slitasjeutsatte komponenter før feil inntreffer, hjelper til med å forhindre uventede avbrudd og reduserer totale vedlikeholdskostnader. Artikler som pakninger, filtre og kjølesystemkomponenter har forutsigbare levetider som kan håndteres gjennom proaktive utskiftingsprogrammer. Denne tilnærmingen minimerer risikoen for sekundær skade som ofte følger med komponentfeil i komplekse elektriske anlegg.

Vedlikehold av reservedelslager sikrer tilgjengelighet av kritiske komponenter når det trengs, samtidig som lagerkostnader for saktegående varer minimeres. Å etablere relasjoner med pålitelige leverandører og holde passende lagermengder av nødvendige deler støtter effektive vedlikeholdsoperasjoner. Det bør også etableres prosedyrer for nødinnkjøp i situasjoner som krever umiddelbar tilgjengelighet av deler.

Oppgraderingsmuligheter under planlagte vedlikeholdsstopp kan forbedre utstyrets ytelse, pålitelighet og sikkerhet samtidig som eksisterende nedetid utnyttes. Moderne overvåkingssystemer, bedre beskyttelsesanordninger og forbedrede kjølekomponenter gir ofte betydelige fordeler når de integreres i eksisterende transformatorinstallasjoner. Kostnad-nytte-analyse av potensielle oppgraderinger hjelper til med å prioritere forbedringer som gir størst avkastning på investeringen.

Sikkerhetsprotokoller og miljøhensyn

Personlig verneutstyr og trygge arbeidsmetoder

Vedlikehold av oljetransformatorer innebærer flere sikkerhetsrisikoer, inkludert elektrisk støt, lysbueeksplosjon, eksponering for kjemikalier og brannfare, som krever omfattende sikkerhetsprotokoller. Valg av personlig verneutstyr må ta hensyn til alle potensielle farer som er til stede under spesifikke vedlikeholdsarbeider. Riktig opplæring i sikkerhetsprosedyrer og nødprosedyrer sikrer at vedlikeholdsansatte kan arbeide trygt samtidig som de effektivt fullfører nødvendige oppgaver.

Låsing og merking (lockout and tagout) forhindrer utilsiktet strømtilførsel til utstyr under vedlikeholdsarbeid og beskytter arbeidere mot elektriske farer. Disse prosedyrene krever nøye koordinering med driftspersonell og tydelig kommunikasjon om arbeidsgrenser og tidsplan. Verifisering av strømløse tilstander gjennom riktige testprosedyrer gir ytterligere beskyttelse mot uventede elektriske farer.

Brannforebyggende tiltak blir spesielt viktig når man arbeider med oljefylte elektriske anlegg på grunn av transformatoroljens brennbare natur. Varmearbeidstillatelser, brannvaktprosedyrer og raskt tilgjengelig brannslukkeutstyr bidrar til å minimere brannrisiko under vedlikeholdsarbeid. Beredskapsplanlegging sikrer rask og effektiv handling i tilfelle ulykker eller utstyrssvikt under vedlikeholdsarbeid.

Miljøvernområder

Tiltak for forebygging og innkapsling av oljeutslipp beskytter jord og grunnvann mot forurensning under rutinevedlikehold og i nødssituasjoner. Sekundærinnkapsling, utslippssett for rask innsats og opplærte beredskapspersoner hjelper til med å redusere miljøpåvirkningen når oljeutslipp inntreffer. Regelmessig inspeksjon og testing av innkapslingssystemer sikrer at de fungerer effektivt når de trengs.

Riktig deponering av avfallsmaterialer som genereres under vedlikehold av oljetransformatorer forutsetter overholdelse av miljøregelverk og bruk av sertifiserte avfallshåndteringskontraktører. Brukt olje, forurenset materiale og utskiftede komponenter må håndteres i henhold til gjeldende miljøstandarder. Dokumentasjon av avfallsdeponeringsaktiviteter støtter målene for regelverksmessig overholdelse og miljøansvar.

PCB-testing og håndteringsprosedyrer tar for seg eldre transformatorer som kan inneholde polyklorerte bifenyler, som krever spesielle håndterings- og deponeringsprosedyrer. Regelmessig testing bekrefter konsentrasjonen av PCB og sikrer overholdelse av regelverk for utstyr som inneholder disse stoffene. Riktig merking og dokumentasjon av utstyr som inneholder PCB støtter trygg håndtering og regelverksmessig overholdelse gjennom hele utstyrets levetid.

Ofte stilte spørsmål

Hvor ofte bør olje i oljetransformator testes

Oljekontrollens frekvens avhenger av transformatorens alder, kritikalitet og driftsforhold, men er vanligvis fra årlig for nyere enheter til kvartalsvis for eldre eller mer kritiske anlegg. Høyspenttransformatorer og slike som betjener essensielle laster, krever typisk hyppigere testing enn transformatorer på distribusjonsnivå. Nødtesting kan være nødvendig etter elektriske feil, ekstreme værforhold eller andre uvanlige driftsforhold som kan påvirke oljekvaliteten.

Hva er advarselstegnene på problemer med oljetransformatorer

Vanlige advarselstegn inkluderer uvanlige driftstemperaturer, unormale lyder som brumming eller knaking, synlige oljelekkasjer, endringer i oljenivå eller farge, og utløsning av beskyttelsesreléer. Gassoppsamling i konservertanker, utløsing av trykkløsningsanordninger og plutselige endringer i elektriske parametere indikerer også potensielle problemer som krever umiddelbar etterforskning. Regelmessig overvåking av disse indikatorene hjelper med å identifisere problemer før de utvikler seg til alvorlige feil.

Kan transformatorolje renses i stedet for å bli erstattet

Transformatorolje kan ofte renses ved hjelp av prosesser som filtrering, avgassing og kjemisk behandling for å fjerne forurensninger og gjenopprette dielektriske egenskaper. Valget mellom rensing og erstatning avhenger av omfanget av forurensningen, kostnadsbetraktninger og oljens evne til å oppfylle kravene etter behandlingen. Alvorlig forurensning eller kjemisk nedbrytning kan gjøre det nødvendig med fullstendig oljeutskifting i stedet for rensing.

Hvilke sikkerhetstiltak er påkrevd under vedlikehold av oljetransformatorer

Viktige sikkerhetstiltak inkluderer riktige prosedyrer for låsing og merking, bruk av egnet personlig verneutstyr, brannforebyggende tiltak og overholdelse av krav til inngang i lukkede rom når det er relevant. Arbeidere må ha opplæring i elektrisk sikkerhet, kjemikaliesikkerhet og beredskapsprosedyrer. Tiltak for miljøbeskyttelse, som utslippskontroll og korrekt avfallshåndtering, er også kritiske deler av trygge vedlikeholdsprosedyrer.