Understanding Modern Power Transformer Technologies

Power transformers serve as the backbone of electrical distribution systems, playing a crucial role in voltage regulation and power transmission across vast networks. As technology advances, the choice between oil-immersed and dry-type power transformers becomes increasingly significant for engineers, facility managers, and energy professionals. Each type offers distinct advantages and comes with specific considerations that can impact performance, maintenance, and overall system reliability.

The evolution of power transformer technology has led to significant improvements in both oil-immersed and dry-type designs. These advancements address various operational challenges while meeting stringent safety and environmental requirements. Understanding the fundamental differences between these two transformer types is essential for making informed decisions in power distribution system planning.

Core Design and Construction Features

Oil-Immersed Transformer Architecture

Oil-immersed power transformers utilize mineral oil or synthetic fluids as both a cooling medium and electrical insulation. The core and windings are completely submerged in the insulating fluid, which efficiently dissipates heat generated during operation. The design typically includes radiators or cooling fins that facilitate natural or forced oil circulation, enhancing the cooling process.

The transformer tank houses the entire assembly and includes expansion vessels to accommodate oil volume changes due to temperature fluctuations. Advanced monitoring systems track oil temperature, pressure, and quality to ensure optimal performance and early detection of potential issues.

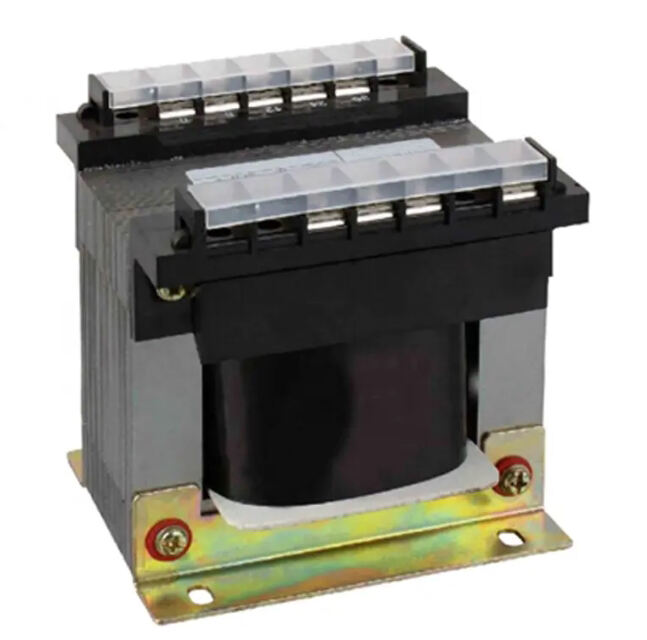

Dry-Type Transformer Construction

Dry-type power transformers employ air as the primary cooling medium, with windings encapsulated in solid insulating materials such as epoxy resin. The core and coil assembly is typically enclosed in a protective housing with ventilation openings that allow air circulation. This design eliminates the need for liquid insulation while maintaining effective cooling capabilities.

The encapsulation process creates a robust barrier against environmental factors and provides excellent mechanical strength. Modern dry-type transformers often incorporate advanced materials and manufacturing techniques to enhance their thermal performance and reliability.

Performance and Operational Characteristics

Cooling Efficiency Analysis

Oil-immersed power transformers generally demonstrate superior cooling properties due to the excellent heat transfer characteristics of insulating oils. The liquid medium enables efficient heat dissipation, allowing these transformers to handle higher power ratings and maintain cooler operating temperatures under heavy loads.

Dry-type transformers, while effective for their intended applications, may require additional cooling considerations for high-power applications. However, advances in materials science and design optimization have significantly improved their thermal management capabilities, making them increasingly competitive in various power ranges.

Load Handling and Capacity

When it comes to power handling capability, oil-immersed transformers typically offer advantages in high-power applications. The superior cooling properties of oil allow these units to manage temporary overloads more effectively while maintaining stable temperature profiles. This characteristic makes them particularly suitable for industrial applications with variable load patterns.

Dry-type power transformers excel in applications requiring moderate power levels and show excellent performance stability under normal operating conditions. Their design allows for reliable operation in environments where consistent loading patterns are maintained, though they may require more conservative sizing for applications with frequent load variations.

Environmental and Safety Considerations

Environmental Impact Assessment

Oil-immersed transformers require careful consideration regarding environmental protection. The potential for oil leaks necessitates containment measures and regular monitoring. However, modern biodegradable oils and improved sealing technologies have significantly reduced environmental risks associated with these units.

Dry-type power transformers offer inherent environmental advantages due to the absence of insulating fluids. This characteristic eliminates the risk of ground contamination and simplifies environmental compliance requirements. Their design aligns well with growing environmental consciousness in power infrastructure planning.

Safety Protocols and Fire Risk

The fire safety profile of dry-type transformers is notably superior, as they eliminate the fire risks associated with insulating oils. This makes them particularly suitable for indoor installations, hospitals, commercial buildings, and other locations where fire safety is paramount. Their self-extinguishing properties provide an additional layer of safety assurance.

Oil-immersed transformers require comprehensive fire protection systems and careful placement considerations. However, modern fire-resistant oils and advanced safety features have significantly improved their safety profile, making them viable options even in sensitive installations when proper precautions are implemented.

Maintenance Requirements and Lifecycle Costs

Routine Maintenance Procedures

The maintenance requirements for oil-immersed power transformers include regular oil testing, filtering, and potential replacement of insulating fluid over time. These units require monitoring of oil quality parameters and periodic inspection of seals and gaskets to prevent leakage. However, when properly maintained, they often demonstrate exceptional longevity and reliable performance.

Dry-type transformers typically require less intensive maintenance, primarily focusing on cleaning, inspection of connections, and monitoring of environmental conditions. Their solid insulation system eliminates the need for fluid maintenance, though regular inspection of ventilation systems and insulation condition remains important.

Long-term Cost Analysis

Initial investment costs for oil-immersed transformers may be lower for higher power ratings, but their total lifecycle costs must consider oil maintenance, environmental compliance, and safety system requirements. The long-term reliability and efficient operation of these units often justify their maintenance requirements.

Dry-type power transformers generally command higher initial costs but may offer lower lifetime maintenance expenses. Their simplified maintenance requirements and reduced environmental compliance needs can result in favorable long-term economics, particularly in applications where installation space and safety considerations are primary factors.

Installation and Space Requirements

Location and Space Considerations

Oil-immersed transformers typically require outdoor installation or dedicated transformer vaults with appropriate containment systems. Their installation must account for oil handling equipment access and maintenance clearances. The space requirements include provisions for cooling equipment and oil containment structures.

Dry-type power transformers offer greater flexibility in installation locations, including indoor spaces close to load centers. Their compact design and simpler ventilation requirements often result in reduced space needs, though adequate airflow must still be ensured for proper cooling.

Installation Infrastructure Requirements

The installation of oil-immersed transformers necessitates comprehensive infrastructure including oil containment systems, fire suppression equipment, and sometimes specialized foundations. These requirements can impact project complexity and timeline but are essential for safe operation.

Dry-type transformers generally require simpler installation infrastructure, focusing primarily on ventilation and basic fire protection systems. Their installation process is often more straightforward, potentially reducing project duration and complexity while maintaining high safety standards.

Frequently Asked Questions

What determines the choice between oil-immersed and dry-type power transformers?

The selection depends on various factors including power rating requirements, installation location, environmental conditions, maintenance capabilities, and safety considerations. Oil-immersed units are often preferred for high-power applications and outdoor installations, while dry-type transformers excel in indoor locations and environments with stringent safety requirements.

How do environmental conditions affect transformer performance?

Environmental conditions significantly impact transformer operation. Oil-immersed transformers generally handle extreme temperatures better due to their efficient cooling systems, while dry-type units perform well in clean, controlled environments. Humidity, altitude, and ambient temperature all influence the selection and sizing of both transformer types.

What are the key maintenance differences between these transformer types?

Oil-immersed transformers require regular oil testing, filtering, and potential replacement, along with monitoring of oil quality parameters. Dry-type transformers need less intensive maintenance, focusing mainly on cleaning, connection inspection, and environmental condition monitoring. The maintenance strategy significantly impacts the total cost of ownership for both types.