Understanding the Critical Role of Power Distribution Systems

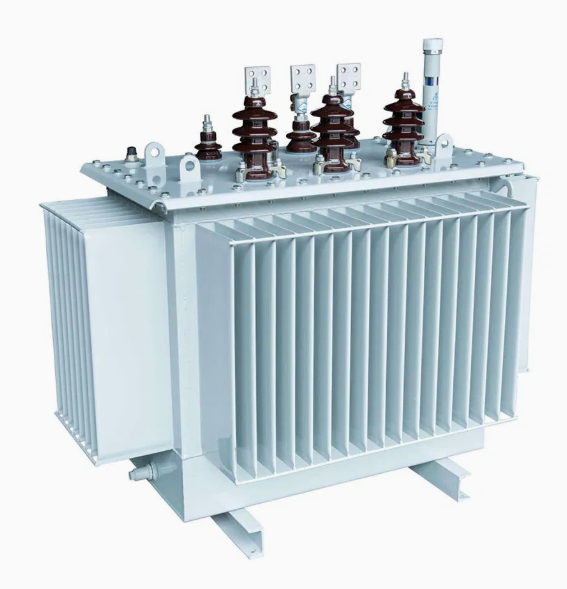

Power distribution systems form the backbone of our electrical infrastructure, and at their heart lies the distribution transformer. These essential devices enable the safe and efficient delivery of electrical power from transmission networks to end-users, making them crucial components for residential, commercial, and industrial applications. Selecting the appropriate distribution transformer requires careful consideration of multiple factors to ensure optimal performance, reliability, and cost-effectiveness.

The modern electrical grid faces increasing demands for efficiency and reliability. Distribution transformers play a pivotal role in meeting these challenges by stepping down high voltage power to usable levels while maintaining system stability. Whether you're planning a new installation or upgrading existing infrastructure, understanding the key aspects of transformer selection will help you make an informed decision.

Technical Specifications and Requirements

Power Rating and Capacity Planning

The first step in selecting a distribution transformer involves determining the required power rating. This calculation must account for both current needs and future expansion possibilities. A properly sized transformer should handle peak loads while maintaining some reserve capacity for potential growth. Engineers typically recommend sizing the distribution transformer at 130% of the expected maximum load to ensure reliable operation and longevity.

Load analysis plays a crucial role in capacity planning. Consider factors such as daily load patterns, seasonal variations, and potential future developments in the service area. Remember that undersizing can lead to overheating and reduced transformer life, while oversizing results in unnecessary capital expenditure and reduced efficiency.

Voltage Requirements and Regulation

Voltage specifications must match both the primary supply voltage and the required secondary distribution voltage. The distribution transformer should maintain stable output voltage within acceptable tolerances despite input fluctuations. Modern units typically offer regulation capabilities of ±2.5% to ±5%, with taps for fine-tuning output voltage.

Consider the impact of voltage drop across the secondary distribution network when selecting transformer specifications. The chosen unit must compensate for these losses while maintaining voltage stability at the point of use. Advanced voltage regulation features may be necessary for applications with sensitive equipment or varying load conditions.

Environmental and Installation Considerations

Location and Environmental Factors

The installation environment significantly influences the selection of a distribution transformer. Indoor installations require different specifications compared to outdoor units exposed to weather elements. Consider factors such as ambient temperature, humidity levels, altitude, and exposure to corrosive elements when selecting the appropriate model.

Environmental protection ratings (IP ratings) must match the installation location's conditions. Coastal areas may require special corrosion-resistant designs, while high-altitude installations need appropriate derating factors. The chosen transformer must also comply with local environmental regulations regarding noise levels and oil containment.

Space and Accessibility Requirements

Physical dimensions and weight constraints play a crucial role in transformer selection. Ensure adequate clearance for ventilation, maintenance access, and safety requirements. Consider the available space for installation, including height restrictions and floor loading capacity. Some installations may require special configurations such as pad-mounted or pole-mounted designs.

Access requirements for maintenance and potential replacement must be factored into the selection process. This includes considerations for oil sampling, cooling system maintenance, and emergency replacement procedures. The chosen design should facilitate these activities while maintaining safety and reliability.

Efficiency and Operating Costs

Energy Efficiency Standards

Modern distribution transformers must meet increasingly stringent efficiency standards. High-efficiency units may cost more initially but offer significant savings over their operational lifetime. Consider the total cost of ownership, including energy losses, when comparing different models. The latest energy efficiency regulations often specify minimum performance requirements for various capacity ranges.

Core losses and copper losses contribute to the overall efficiency of a distribution transformer. Advanced core materials and innovative designs can significantly reduce these losses. Evaluate the load profile and energy costs to determine the optimal efficiency level for your application.

Maintenance and Lifetime Costs

Regular maintenance requirements and expected service life significantly impact the total cost of ownership. Choose designs that offer reliable operation with minimal maintenance needs. Consider factors such as oil testing intervals, cooling system maintenance, and component replacement schedules when evaluating different options.

The initial purchase price represents only a fraction of the lifetime cost. Calculate the total cost of ownership including installation, maintenance, energy losses, and eventual replacement. High-quality distribution transformers often prove more economical over their service life despite higher upfront costs.

Frequently Asked Questions

What factors affect the lifespan of a distribution transformer?

The lifespan of a distribution transformer is influenced by several key factors including loading patterns, environmental conditions, maintenance practices, and initial design quality. Regular maintenance, proper loading within rated capacity, and protection from environmental stresses can significantly extend service life. Most well-maintained units can operate reliably for 25-30 years or more.

How do I determine the correct size for a distribution transformer?

Sizing a distribution transformer requires careful analysis of current and future load requirements. Calculate the total connected load, consider diversity factors, and add a safety margin of approximately 30%. Account for potential load growth and seasonal variations. Working with experienced electrical engineers can help ensure accurate sizing decisions.

What are the key maintenance requirements for distribution transformers?

Regular maintenance typically includes oil testing, inspection of cooling systems, monitoring of load patterns, and checking for signs of deterioration. The frequency of maintenance activities depends on the installation environment and loading conditions. Develop a comprehensive maintenance schedule based on manufacturer recommendations and industry best practices to ensure reliable operation.

How can I maximize energy efficiency in transformer operations?

Maximize efficiency by selecting the appropriate capacity, maintaining proper loading levels, and choosing high-efficiency designs. Regular monitoring of performance parameters, proper maintenance, and addressing issues promptly help maintain optimal efficiency. Consider upgrading older units to modern high-efficiency models when replacement becomes necessary.