The financial implications of installing a modern substation transformer extend far beyond the initial equipment purchase price. Industrial facilities, utility companies, and infrastructure developers must carefully evaluate multiple cost components to ensure optimal return on investment and long-term operational efficiency. Understanding the comprehensive cost structure helps organizations make informed decisions that align with both budgetary constraints and operational requirements.

Modern electrical infrastructure demands sophisticated transformer solutions that can handle increasing power loads while maintaining reliability and efficiency. The evolution of transformer technology has introduced new materials, design methodologies, and installation techniques that significantly impact overall project costs. Contemporary substation transformer installations require careful consideration of environmental factors, regulatory compliance, and future scalability requirements that influence total investment calculations.

Initial Equipment and Procurement Costs

Transformer Unit Pricing Structure

The base cost of a substation transformer varies significantly based on power rating, voltage class, and technical specifications. Standard distribution transformers typically range from moderate pricing for smaller units to substantial investments for high-capacity installations. Power ratings directly correlate with material requirements, manufacturing complexity, and transportation considerations that affect final pricing structures.

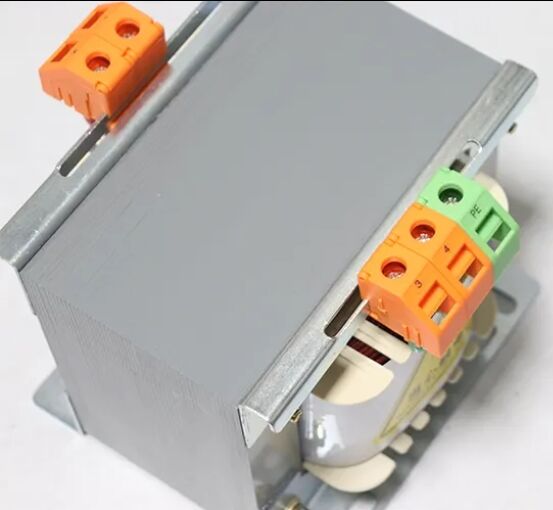

Premium features such as advanced cooling systems, enhanced insulation materials, and integrated monitoring capabilities add considerable value to transformer units. These technological enhancements often justify higher initial costs through improved efficiency, reduced maintenance requirements, and extended operational lifespan. Manufacturers typically offer various configuration options that allow customers to balance initial investment against long-term operational benefits.

Quality and Certification Requirements

Industry standards and certification requirements significantly influence transformer procurement costs. International standards such as IEC and IEEE specifications ensure compatibility and performance reliability but may increase manufacturing costs due to stringent testing and documentation requirements. Certified transformers provide assurance of quality and performance but command premium pricing compared to non-certified alternatives.

Regional certification requirements vary considerably, with some markets demanding additional testing protocols and documentation standards. These regulatory compliance costs are typically incorporated into the equipment pricing structure but may require separate budget allocation for specialized testing or third-party verification services. Understanding local certification requirements helps organizations avoid unexpected costs during procurement processes.

Installation and Infrastructure Development

Site Preparation and Civil Works

Substation transformer installation requires extensive site preparation that can represent a significant portion of total project costs. Foundation requirements depend on transformer size, weight, and local soil conditions, with larger units requiring reinforced concrete foundations and specialized drainage systems. Site accessibility considerations may necessitate road improvements or temporary construction access routes that add to overall project expenses.

Environmental considerations increasingly influence site preparation costs as regulatory requirements become more stringent. Noise mitigation measures, visual screening, and environmental impact assessments are becoming standard requirements that affect project timelines and budgets. Modern installations often incorporate landscaping and architectural elements that enhance community acceptance but increase overall development costs.

Transportation and Handling Requirements

Large substation transformer units require specialized transportation equipment and careful logistics planning that contribute significantly to installation costs. Oversized load permits, escort vehicles, and route surveys are standard requirements for transformer transportation that must be factored into project budgets. Remote installation locations may require additional transportation considerations such as temporary bridges or road reinforcement.

Installation crane requirements represent another major cost component, with large transformers requiring heavy-lift cranes and experienced operators. Crane mobilization costs, site preparation for crane operation, and extended rental periods during installation contribute to overall project expenses. Weather delays and seasonal accessibility limitations can further impact crane costs and project scheduling.

Operational and Maintenance Cost Considerations

Energy Efficiency and Loss Calculations

Operating efficiency directly impacts long-term cost performance, with transformer losses representing ongoing operational expenses throughout the equipment lifespan. No-load losses occur continuously regardless of loading conditions, while load losses vary with electrical demand patterns. Modern transformer designs focus on minimizing both loss categories to reduce operational costs and environmental impact.

Energy cost calculations must consider local utility rates, demand charges, and potential future rate increases when evaluating transformer efficiency options. High-efficiency transformers typically command premium pricing but often provide attractive payback periods through reduced energy costs. Life-cycle cost analysis helps organizations determine optimal efficiency levels that balance initial investment against operational savings.

Preventive Maintenance Programs

Scheduled maintenance requirements vary considerably between transformer types and operating environments, with maintenance costs representing significant ongoing operational expenses. Oil-filled transformers require regular oil testing, filtration, and replacement services that must be performed by qualified technicians. Dry-type transformers typically have lower maintenance requirements but may require more frequent cleaning and inspection procedures.

Modern monitoring systems can reduce maintenance costs by providing early warning of potential problems and optimizing maintenance scheduling. Condition-based maintenance strategies help organizations avoid unnecessary service procedures while ensuring reliable operation. Investment in advanced monitoring capabilities often provides attractive returns through reduced maintenance costs and improved equipment reliability.

Regulatory Compliance and Environmental Factors

Environmental Impact Assessment Costs

Environmental compliance requirements increasingly influence substation transformer project costs as regulatory frameworks become more comprehensive. Environmental impact studies, soil contamination assessments, and wildlife habitat evaluations are becoming standard project requirements that affect budgets and timelines. These assessments help organizations identify potential environmental liabilities and mitigation measures.

Noise pollution regulations particularly affect transformer installations in urban or residential areas, potentially requiring sound mitigation measures or specialized low-noise equipment. Visual impact considerations may necessitate architectural screening or underground installation options that significantly increase project costs. Understanding local environmental requirements helps organizations develop realistic project budgets and timelines.

Safety and Code Compliance Requirements

Electrical safety codes and installation standards continue evolving, requiring ongoing compliance investments throughout transformer lifecycles. Arc flash protection, grounding systems, and clearance requirements may necessitate infrastructure modifications or equipment upgrades that affect long-term cost projections. Safety training requirements for maintenance personnel represent ongoing operational costs that must be considered in total cost calculations.

Fire protection systems for oil-filled transformers require specialized equipment and ongoing maintenance that contributes to operational costs. Automatic fire suppression systems, containment barriers, and emergency response procedures are becoming standard requirements that affect both initial installation costs and ongoing operational expenses. Insurance requirements may mandate specific safety features that influence equipment selection and installation design.

Technology Integration and Future-Proofing

Smart Grid Compatibility Features

Modern substation transformer installations increasingly incorporate smart grid technologies that enhance operational capabilities but require additional investment in communication systems and monitoring equipment. Digital monitoring capabilities provide real-time operational data that improves system reliability and maintenance efficiency. These technological enhancements often justify higher initial costs through improved operational performance and reduced maintenance requirements.

Integration with existing control systems requires careful planning and may necessitate infrastructure upgrades or compatibility modifications that affect project costs. Communication protocols, data management systems, and cybersecurity measures represent growing cost components in modern transformer installations. Future technology upgrade capabilities should be considered when evaluating initial investment options to avoid obsolescence concerns.

Scalability and Expansion Considerations

Future electrical demand growth requires careful consideration during initial transformer sizing and installation design to avoid costly retrofitting or replacement projects. Modular installation approaches may provide cost-effective expansion capabilities but require higher initial infrastructure investment. Load growth projections help organizations balance initial costs against future expansion requirements and potential stranded investment risks.

Infrastructure design flexibility becomes increasingly important as electrical demand patterns evolve and new technologies emerge. Spare capacity provisions, expandable control systems, and future connection capabilities may increase initial costs but provide valuable flexibility for future modifications. Long-term strategic planning helps organizations optimize initial investments while maintaining adaptation capabilities for changing operational requirements.

FAQ

What factors most significantly impact substation transformer installation costs

The most significant cost factors include equipment specifications and power rating, site preparation requirements, transportation logistics, and regulatory compliance needs. Power rating directly affects transformer pricing, while site conditions influence civil work requirements and installation complexity. Remote locations or challenging access conditions can substantially increase transportation and installation costs through specialized equipment requirements and extended project timelines.

How do efficiency ratings affect long-term operational costs

Higher efficiency ratings reduce ongoing energy costs through lower transformer losses but typically require higher initial investment. No-load losses represent continuous operational costs regardless of loading conditions, while load losses vary with electrical demand. Life-cycle cost analysis helps organizations determine optimal efficiency levels by comparing initial premium costs against projected energy savings over the transformer operational lifespan, typically 25-30 years.

What maintenance costs should be expected for modern transformer installations

Maintenance costs vary significantly between transformer types, with oil-filled units requiring regular oil testing, filtration, and replacement services. Dry-type transformers typically have lower maintenance requirements but may need more frequent cleaning and inspection procedures. Modern monitoring systems can reduce maintenance costs by enabling condition-based maintenance strategies and providing early warning of potential problems, helping organizations optimize maintenance scheduling and avoid unnecessary service procedures.

How do environmental regulations influence transformer project budgets

Environmental regulations increasingly require impact assessments, noise mitigation measures, and visual screening that can significantly affect project costs and timelines. Fire protection requirements for oil-filled transformers necessitate specialized containment systems and suppression equipment. Soil contamination assessments and habitat protection measures are becoming standard requirements that must be factored into project budgets, particularly for installations in environmentally sensitive areas or urban locations with strict noise and visual impact requirements.