The Evolution of Modern Power Distribution Solutions

The electrical industry has witnessed remarkable transformations over the decades, with dry transformers emerging as a cornerstone of efficient and safe power distribution. These innovative devices have revolutionized how we handle electrical power conversion across various sectors, from industrial facilities to commercial buildings and renewable energy installations.

As we approach 2025, the significance of dry transformers continues to grow, driven by increasing demands for safer, more environmentally conscious power solutions. Unlike their oil-filled counterparts, dry transformers operate without liquid cooling mediums, making them inherently safer and more suitable for indoor installations where fire safety is paramount.

Understanding Dry Transformer Technology

Core Components and Design Features

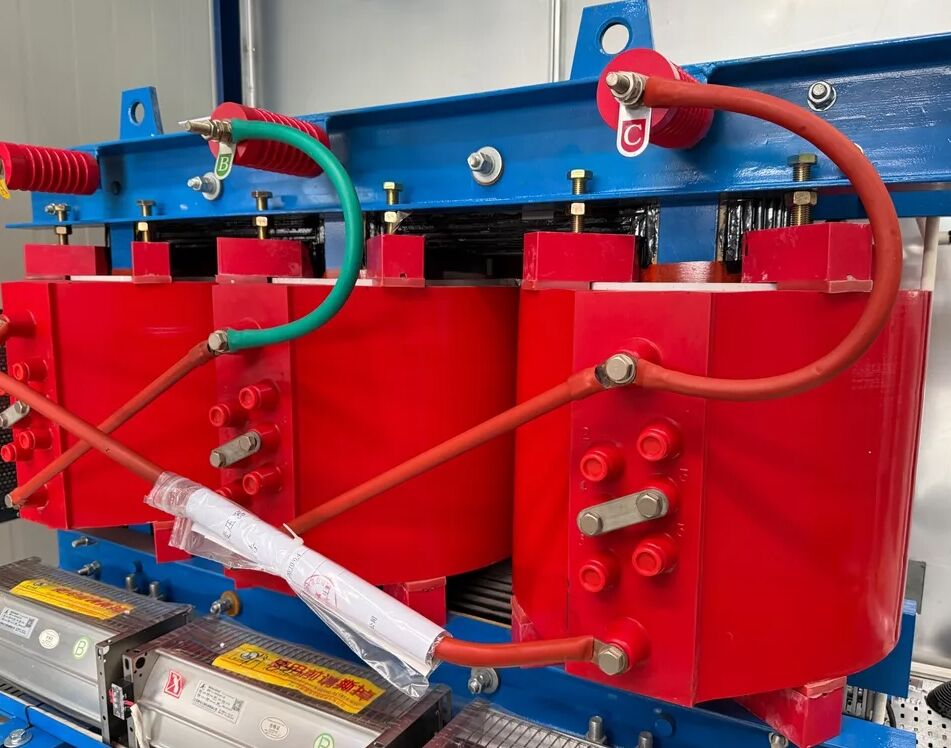

At the heart of every dry transformer lies a sophisticated arrangement of components designed for optimal performance. The core typically consists of high-grade silicon steel laminations, carefully assembled to minimize energy losses. The windings, made from high-purity copper or aluminum, are enclosed in special insulating materials that ensure both electrical isolation and efficient heat dissipation.

Modern dry transformer designs incorporate advanced cooling systems that utilize natural air circulation or forced-air cooling methods. These systems effectively maintain operational temperatures without the need for liquid coolants, contributing to the transformer's reliability and reduced maintenance requirements.

Advanced Insulation Systems

The insulation system in a dry transformer represents a crucial technological advancement. Most contemporary models employ either cast resin or vacuum pressure impregnated (VPI) techniques. Cast resin transformers feature windings that are entirely encased in epoxy resin, providing excellent protection against environmental factors and ensuring consistent performance under varying conditions.

VPI systems, alternatively, use a special process where the windings are impregnated with varnish under vacuum conditions. This creates a robust insulation barrier that effectively resists moisture, dust, and chemical contaminants, while maintaining superior thermal characteristics.

Applications Across Industries

Commercial Building Infrastructure

In commercial buildings, dry transformers serve as essential components of the electrical distribution system. They are commonly installed in office complexes, shopping centers, and hospitals, where their flame-retardant properties and minimal maintenance requirements make them ideal choices. These installations help maintain consistent power supply while ensuring the safety of occupants and valuable equipment.

The versatility of dry transformers allows them to be positioned closer to the load centers, reducing cable losses and improving overall system efficiency. This strategic placement capability has made them increasingly popular in green building designs and LEED-certified structures.

Industrial Manufacturing Facilities

Manufacturing facilities rely heavily on dry transformers to power their operations efficiently and safely. These environments often demand robust power distribution solutions that can withstand harsh conditions while maintaining consistent performance. Dry transformers excel in such settings, providing reliable voltage transformation without the environmental risks associated with oil-filled units.

The ability of dry transformers to handle varying loads and frequent startup conditions makes them particularly valuable in facilities with multiple production lines or heavy machinery. Their compact footprint also allows for flexible installation options, maximizing valuable factory floor space.

Environmental and Safety Benefits

Ecological Advantages

The environmental benefits of dry transformers extend beyond their oil-free operation. These units typically have a longer operational lifespan, reducing the frequency of replacement and associated waste. Their construction materials are generally recyclable, contributing to sustainable industry practices and reduced environmental impact.

Modern dry transformers also demonstrate improved energy efficiency, resulting in lower operational costs and reduced carbon footprint. This aspect has become increasingly important as organizations worldwide strive to meet stringent environmental regulations and sustainability goals.

Safety Features and Compliance

Safety considerations have always been paramount in transformer design, and dry transformers excel in this aspect. Their fire-resistant properties and absence of combustible cooling liquids make them inherently safer than traditional oil-filled transformers. This characteristic is particularly valuable in densely populated areas or facilities where fire safety is a critical concern.

Modern dry transformers are designed to meet or exceed international safety standards and regulations. They often incorporate advanced monitoring systems that can detect potential issues before they become critical, enabling proactive maintenance and preventing unexpected failures.

Maintenance and Lifecycle Considerations

Preventive Maintenance Protocols

One of the most significant advantages of dry transformers is their reduced maintenance requirements compared to oil-filled units. However, regular inspection and maintenance remain essential for optimal performance and longevity. This typically includes periodic visual inspections, cleaning of ventilation systems, and verification of electrical connections.

Advanced diagnostic tools and monitoring systems help facilities managers track transformer performance and schedule maintenance activities efficiently. These predictive maintenance approaches have proven effective in extending equipment life while minimizing operational disruptions.

Long-term Cost Benefits

While the initial investment in a dry transformer may be higher than traditional alternatives, the long-term financial benefits often justify the cost. Reduced maintenance requirements, lower operating costs, and extended service life contribute to a favorable total cost of ownership. Additionally, the elimination of oil handling and disposal costs provides further economic advantages over the equipment's lifecycle.

Organizations implementing dry transformers often report significant insurance premium reductions due to the reduced fire risk. This, combined with energy efficiency savings and minimal maintenance expenses, makes dry transformers an economically sound choice for many applications.

Frequently Asked Questions

What makes dry transformers different from oil-filled transformers?

Dry transformers utilize air or solid insulation materials instead of oil for cooling and insulation. This design eliminates the need for liquid maintenance, reduces fire hazards, and makes them more environmentally friendly. They are typically more compact and require less maintenance than their oil-filled counterparts.

How long can a dry transformer be expected to operate?

Under proper maintenance and operating conditions, a dry transformer can typically last 20-30 years or more. The actual lifespan depends on various factors including loading conditions, environmental factors, and maintenance practices. Regular monitoring and preventive maintenance can significantly extend their operational life.

Are dry transformers suitable for outdoor installations?

While dry transformers are primarily designed for indoor use, specially encased versions are available for outdoor installations. These models feature enhanced protection against environmental factors such as moisture, dust, and extreme temperatures. However, proper enclosure and protection measures must be implemented to ensure reliable operation in outdoor settings.