گزشتہ کئی دہائیوں کے دوران ٹرانسفارمر کی ڈیزائن میں بجلی کی صنعت میں تکنیکی پیش رفت نے قابلِ ذکر ترقی کی ہے۔ جبکہ روایتی آئل ٹرانسفارمر سسٹمز نے نسل در نسل مارکیٹ پر حاوی رہے، خشک قسم کے ٹرانسفارمر ایک قابلِ مقابلہ متبادل کے طور پر ابھر کر سامنے آئے ہیں جو روایتی ٹرانسفارمر حلول سے وابستہ بہت سے سیفٹی، ماحولیاتی اور دیکھ بھال کے معاملات کا احاطہ کرتے ہی ہیں۔ یہ تخلیقی برقی آلات فوائد کی ایک حد پیش کرتے ہیں جو انہیں صنعتی اطلاقات، تجارتی عمارتوں اور ان خصوصی تنصیبات کے لیے مزید متوجہ کن بناتے ہیں جہاں سیفٹی اور ماحولیاتی تقاضے نہایت اہمیت کے حامل ہوتے ہیں۔

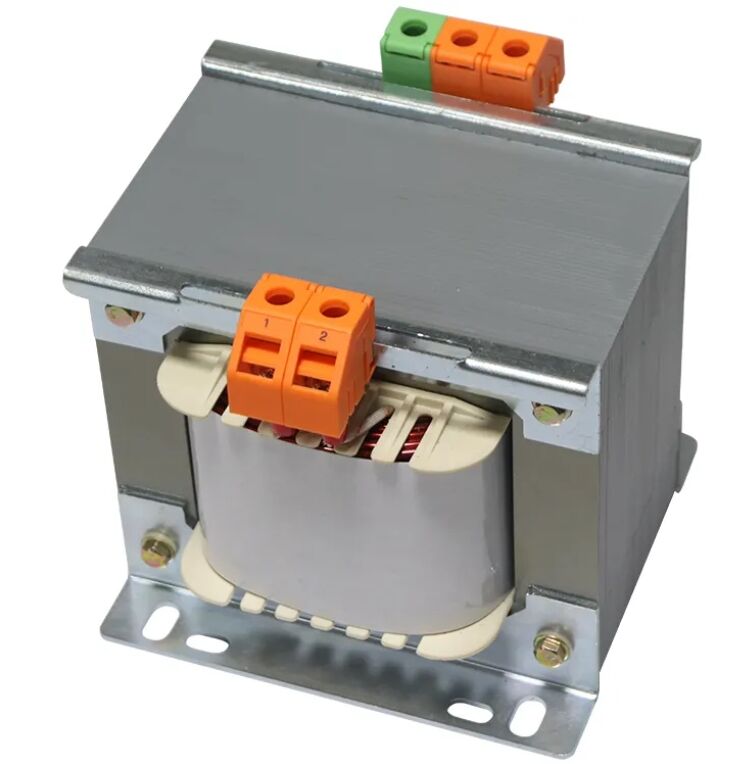

خشک قسم کے ٹرانسفارمرز اور تیل سے بھرے ہوئے ٹرانسفارمرز کے درمیان بنیادی فرق کو سمجھنا بجلی کی بنیادی ڈھانچے کی سرمایہ کاری کے بارے میں آگاہی پر مبنی فیصلے کرنے کے لیے نہایت ضروری ہے۔ خشک قسم کے ٹرانسفارمرز عزل اور تبريد کے لیے ہوا یا رال انکیپسولیشن کا استعمال کرتے ہیں، جس سے روایتی ٹرانسفارمر ڈیزائنز کی خصوصیت رکھنے والے عزلی تیل کی ضرورت ختم ہو جاتی ہے۔ اس بنیادی ڈیزائن کے فرق کی وجہ سے مسلسل فوائد پیدا ہوتے ہیں جو مختلف صنعتی درخواستوں میں حفاظتی طریقہ کار، دیکھ بھال کی ضروریات، ماحولیاتی مطابقت اور مجموعی آپریشنل کارکردگی کو متاثر کرتے ہیں۔

بہتر حفاظتی خصوصیات اور آگ کی روک تھام

آگ اور دھماکے کے خطرات کا خاتمہ

ڈرائی قسم کے ٹرانسفارمرز کے سب سے اہم فوائد میں سے ایک روایتی تیل والے ٹرانسفارمر یونٹس کے مقابلے میں ان کا بنیادی طور پر زیادہ محفوظ آپریشن ہے۔ قابلِ اشتعال عاید تیل کی عدم موجودگی بجلی کے انسٹالیشن میں آگ اور دھماکے کے خطرات کو نمایاں حد تک کم کر دیتی ہے۔ تیل سے بھرے ٹرانسفارمرز میں، اندرونی خرابیاں تیل کے ٹوٹنے، گیس کی تشکیل اور بالآخر آگ یا دھماکوں کی صورت میں تباہ کن ناکامیوں کا باعث بن سکتی ہیں۔ ڈرائی قسم کے ٹرانسفارمرز اس خطرے کو مکمل طور پر اپنی تیل سے پاک ڈیزائن کے ذریعے ختم کر دیتے ہیں۔

محفوظ ہونے کے فوائد صرف بنیادی آگ کی روک تھام تک محدود نہیں ہیں بلکہ خصوصی آگ بجھانے کے نظام کی کم ضروریات بھی شامل ہیں۔ جہاں ڈرائی قسم کے ٹرانسفارمرز استعمال ہوتے ہیں، وہاں اکثر آگ کی حفاظت کے لیے سادہ اقدامات کافی ہوتے ہیں، جس سے انسٹالیشن کی لاگت اور مستقل مرمت کے اخراجات دونوں کم ہوتے ہیں۔ نیز، تیل کی عدم موجودگی سے صنعتی ماحول میں پھسلن کے خطرات یا ماحولیاتی آلودگی کے بارے میں تشویش بھی ختم ہو جاتی ہے۔

بہتر اندر انسٹالیشن کی لچک

خشک قسم کے ٹرانسفارمرز کے حفاظتی فوائد عمارتوں اور صنعتی سہولیات کے اندر انسٹالیشن کی جگہوں میں زیادہ لچک فراہم کرتے ہیں۔ تیل والے ٹرانسفارمر سسٹمز کے برعکس جن کے لیے عام طور پر خصوصی وینٹی لیشن اور فائر سپریشن سسٹمز کے ساتھ علیحدہ ٹرانسفارمر کمروں کی ضرورت ہوتی ہے، خشک قسم کے یونٹس معیاری عمارت کی بنیادی سہولیات کے ساتھ مختلف اندر کی جگہوں پر انسٹال کیے جا سکتے ہیں۔ یہ لچک زیادہ موثر جگہ کے استعمال کی اجازت دیتی ہے اور مہنگی بنیادی ڈھانچے کی ترمیم کی ضرورت کو کم کرتی ہے۔

بہتر حفاظتی کردار کا مطلب یہ بھی ہے کہ خشک قسم کے ٹرانسفارمرز لوڈ سنٹرز کے قریب تر انسٹال کیے جا سکتے ہیں بغیر تیل سے بھرے یونٹس کے ساتھ منسلک حفاظتی تشویشوں کے اسی سطح کے۔ یہ قربت ٹرانسمیشن نقصانات کو کم کرتی ہے اور مجموعی سسٹم کی کارکردگی میں بہتری لاتی ہے جبکہ عملے اور آلات کی حفاظت کے لیے سب سے زیادہ حفاظتی معیارات برقرار رکھتی ہے۔

کم ترین مرمت کی ضروریات اور آپریشنل کارآمدی

آسان شدہ مرمت کے پروٹوکول

خشک قسم کے ٹرانسفارمرز روایتی تیل ٹرانسفارمر سسٹمز کے مقابلے میں دیکھ بھال کی ضروریات میں نمایاں فوائد فراہم کرتے ہیں۔ عایق تیل کے خاتمے سے باقاعدہ تیل کی نمونہ جاتی، جانچ اور تبدیلی کی طریق کار کی ضرورت ختم ہو جاتی ہے جو تیل سے بھرے ٹرانسفارمرز کی کارکردگی اور حفاظت کو برقرار رکھنے کے لیے ضروری ہوتی ہے۔ اس سادگی کا مطلب ہے دیکھ بھال کی کم لاگت، کم منصوبہ بندی شدہ بندشیں، اور تیل کو سنبھالنے کے ماہرین پر کم انحصار۔

تیل کی عدم موجودگی سے تیل کی کیفیت کو برقرار رکھنے کے لیے درکار نگرانی کے نظام کے بارے میں تشویش، نمی کے اثرات اور تیل کی خرابی کے بارے میں تشویش بھی ختم ہو جاتی ہے۔ روایتی تیل ٹرانسفارمر کی دیکھ بھال میں تیل کی فلٹریشن، گیس نکالنے اور کیمیائی تجزیہ جیسی پیچیدہ کارروائیاں شامل ہوتی ہیں جن کے لیے ماہر آلات اور تربیت یافتہ عملے کی ضرورت ہوتی ہے۔ خشک قسم کے ٹرانسفارمر ان تمام ضروریات سے بالکل مبرا ہوتے ہیں، جس کے نتیجے میں دیکھ بھال کے معمول میں صرف بصری معائنہ اور بنیادی برقی جانچ پر توجہ مرکوز ہوتی ہے۔

مدتِ خدمات کا اضافہ اور مطمئنی

خشک قسم کے ٹرانسفارمرز کی ڈیزائن خصوصیات انہیں بہتر قابل اعتمادیت اور طویل معمولی زندگی فراہم کرتی ہیں جو بہت سے تیل والے ٹرانسفارمر انسٹالیشنز کے مقابلے میں بہتر ہوتی ہے۔ تیل کی عدم موجودگی حرارتی سائیکلنگ، آکسیڈیشن اور آلودگی سے وابستہ تخریب کے عمل کو ختم کر دیتی ہے جو وقتاً فوقتاً تیل سے بھرے ٹرانسفارمر کی کارکردگی کو متاثر کر سکتے ہیں۔ نیز، خشک قسم کے ٹرانسفارمرز میں استعمال ہونے والے ٹھوس عایق نظام ماحولیاتی عوامل کی وجہ سے تدریجی تباہی کے لحاظ سے کم متاثر ہوتے ہیں۔

جدید خشک قسم کے ٹرانسفارمرز جدید عایق مواد اور تیاری کی تکنیک کو شامل کرتے ہیں جو بہترین حرارتی کارکردگی اور میکانیکی استحکام فراہم کرتے ہیں۔ ان ڈیزائن میں بہتری کے نتیجے میں ٹرانسفارمرز حاصل ہوتے ہیں جو اپنی مدتِ ملازمت کے دوران کم سے کم مداخلت کے ساتھ قابل اعتماد آپریشن برقرار رکھ سکتے ہیں، جس سے ملکیت کی کل لاگت کم ہوتی ہے اور اہم درخواستوں کے لیے سسٹم دستیابی میں بہتری آتی ہے۔

ماحولیاتی مطابقت اور پائیداری کے فوائد

تیل کی آلودگی کا کوئی خطرہ نہیں

صنعتی آپریشنز میں ماحولیاتی تحفظ کی اہمیت میں اضافہ ہوا ہے، اور خشک قسم کے ٹرانسفارمرز روایتی تیل والے ٹرانسفارمر سسٹمز کے مقابلے میں اس معاملے میں قابلِ ذکر فوائد فراہم کرتے ہیں۔ عایدی تیل کی مکمل عدم موجودگی اس خطرے کو ختم کر دیتی ہے جو مٹی اور زمینی سطح کے پانی کو آلودہ کرنے کا باعث بنتا ہے، جو تیل سے بھرے ٹرانسفارمرز میں رساو، حادثاتی بہاؤ یا تباہ کن ناکامی کی صورت میں ہو سکتا ہے۔ یہ ماحولیاتی حفاظتی خصوصیت خاص طور پر ان اداروں میں قدر کی حامل ہے جو حساس ماحولیاتی علاقوں کے قریب واقع ہیں یا جہاں زمینی سطح کے پانی کے تحفظ کی ضرورت ہوتی ہے۔

ماحولیاتی فوائد ٹرانسفارمر کی خدمت کی زندگی کے خاتمے پر تنصیب ختم کرنے اور تلف کرنے کے طریقوں تک پھیلے ہوئے ہیں۔ ٹرنس فارمر کا تیل ان یونٹس کے برعکس جن میں تیل کی احتیاط سے بازیابی اور تلف کرنے کے طریقے درکار ہوتے ہیں، خشک قسم کے ٹرانسفارمرز کو معیاری دھاتی ری سائیکلنگ کے عمل کے ذریعے آسانی سے ری سائیکل کیا جا سکتا ہے۔ یہ فائدہ طویل مدتی ماحولیاتی ذمہ داری کو کم کرتا ہے اور صنعتی آپریشنز میں پائیدار کاروباری طریقوں کی حمایت کرتا ہے۔

ماحولیاتی ضوابط کی تعمیل

خشک قسم کے ٹرانسفارمرز کی انسٹالیشن کے ساتھ ریگولیٹری کمپلائنس کافی حد تک آسان ہو جاتی ہے۔ بہت سی علاقوں نے ٹرانسفارمر آئل کے ذخیرہ، استعمال اور خاتمے کے حوالے سے سخت ضوابط نافذ کیے ہیں، خاص طور پر پرانی انسٹالیشنز میں موجود PCB والے تیل کے لحاظ سے۔ خشک قسم کے ٹرانسفارمرز ان تمام ضوابط کی خودکار طور پر پابندی کرتے ہیں کیونکہ وہ ڈیزائن میں بالکل تیل کا استعمال ختم کر دیتے ہی ہیں۔

ماحولیاتی کمپلائنس کے فوائد نئی انسٹالیشنز اور سہولیات میں تبدیلی کے لیے منظوری کے عمل تک پھیلے ہوئے ہیں۔ خشک قسم کے ٹرانسفارمرز عام طور پر تیل والے ٹرانسفارمرز کی نسبت کم توسیع شدہ ماحولیاتی جائزہ اور منظوری کی ضرورت ہوتی ہے، خاص طور پر ماحولیاتی طور پر حساس علاقوں یا ان سہولیات میں جہاں ماحولیاتی تحفظ کے سخت تقاضے ہوں۔ اس آسان شدہ منظوری کے عمل سے منصوبے کے شیڈول تیز ہو سکتے ہیں اور ریگولیٹری کمپلائنس کی لاگت کم ہو سکتی ہے۔

معاشی فوائد اور کل ملکیت کی کل لاگت

بنیادی ڈھانچے کی کم ضروریات

خشک قسم کے ٹرانسفارمرز کے معاشی فوائد ان کی ابتدائی خریداری کی قیمت سے آگے بڑھ کر انفراسٹرکچر کی ضروریات میں کمی تک پھیلے ہوئے ہیں۔ تیل والے ٹرانسفارمر سسٹمز کے برعکس جن کے لیے اکثر خصوصی کنٹینمنٹ سسٹمز، تیل جمع کرنے کے گڑھے اور علیحدہ وینٹی لیشن سسٹمز کی ضرورت ہوتی ہے، خشک قسم کے ٹرانسفارمرز کو نہایت کم اضافی انفراسٹرکچر کے ساتھ انسٹال کیا جا سکتا ہے۔ اسسٹنٹ سسٹمز میں کمی کی وجہ سے انسٹالیشن کی لاگت کم ہوتی ہے اور سہولت کے ڈیزائن کی ضروریات میں آسانی پیدا ہوتی ہے۔

خشک قسم کے ٹرانسفارمرز کی جگہ کی موثریت کے فوائد بھی معاشی فوائد میں اضافے کا باعث بنتے ہیں کیونکہ سہولت کا بہتر استعمال ممکن ہوتا ہے۔ خصوصی تیل ہینڈلنگ انفراسٹرکچر کے بغیر معیاری الیکٹریکل کمروں میں ٹرانسفارمرز انسٹال کرنے کی صلاحیت کی بدولت سہولت کے ڈیزائن میں کمپیکٹ نیسہ ممکن ہوتا ہے اور دستیاب جگہ کا بہتر استعمال پیداواری آپریشنز کے لیے ہو سکتا ہے بجائے اس کے کہ وہ سہولت کے انفراسٹرکچر کے لیے استعمال ہو۔

طویل مدتی آپریٹنگ اخراجات میں کمی

اگرچہ خشک قسم کے ٹرانسفارمرز کی ابتدائی لاگت تیل کے ٹرانسفارمرز کے متبادل کے برابر یا تھوڑی زیادہ ہو سکتی ہے، لیکن طویل مدتی چلنے کی لاگت کے فوائد قابلِ ذکر ہوتے ہیں۔ ٹرانسفارمر کی عملی زندگی بھر میں تیل سے متعلقہ دیکھ بھال کی طریق کار، جانچ کی ضروریات اور تبدیلی کی لاگت ختم ہونے سے مسلسل بچت ہوتی ہے۔ نیز، بغیر تیل والی برقی تنصیبات کے ساتھ وابستہ اکثر کم تر انشورنس پریمیمز اضافی مالی فوائد فراہم کر سکتے ہیں۔

عملی کارکردگی کے فوائد میں دیکھ بھال کی طریق کار کے لیے کم وقت کا نقصان اور اسپیئر پارٹس انوینٹری کی ضروریات کو آسان بنانا شامل ہے۔ تیل کو سنبھالنے والے آلات، فلٹریشن سسٹمز اور منسلک نگرانی کے آلات کی عدم موجودگی سے قابلِ بھروسہ آپریشنز کے لیے اسپیئر پارٹس انوینٹری کی پیچیدگی اور لاگت کم ہو جاتی ہے۔

فنی کارکردگی اور استعمال کے اعتبارات

حرارتی انتظامیہ اور کولنگ کی کارآمدگی

جدید خشک قسم کے ٹرانسفارمرز وہ اعلیٰ حرارتی انتظامی نظام استعمال کرتے ہیں جو تیل ٹرانسفارمر کے روایتی ڈیزائن میں موجود حرارتی ماس کے فوائد کے بغیر موثر کولنگ فراہم کرتے ہی ہیں۔ جدید وینٹی لیشن سسٹمز، بہتر کور مواد، اور بہتر وائنڈنگ کی تشکیل خشک قسم کے ٹرانسفارمرز کو مختلف قسم کی آپریٹنگ حالت میں بہترین حرارتی کارکردگی حاصل کرنے کی اجازت دیتی ہے۔

خشک قسم کے ٹرانسفارمرز کی حرارتی خصوصیات انہیں متغیر لوڈ کی حالت یا عارضی آپریشن کے لیے خاص طور پر موزوں بناتی ہیں۔ ہوا سے ٹھنڈا کرنے والے سسٹمز کا تیز حرارتی ردعمل لوڈ میں تبدیلی کے لیے تیل سے بھرے سسٹمز کے ساتھ منسلک حرارتی دیر کے بغیر تیزی سے ایڈجسٹ کرنے کی اجازت دیتا ہے۔ اس تیز ردعمل سے مجموعی سسٹم کی کارکردگی میں بہتری آسکتی ہے اور متحرک لوڈ والی حالت میں توانائی کے استعمال میں کمی آسکتی ہے۔

برقی کارکردگی اور موثریت

خشک قسم کے ٹرانسفارمرز کے ڈیزائن میں ٹیکنالوجیکل ترقی نے برقی کارکردگی کی ایسی سطح حاصل کر لی ہے جو بہت سے اطلاقات میں روایتی تیل والے ٹرانسفارمر سسٹمز کے مقابلے میں مقابلہ کر سکتی ہے یا انہیں پیچھے چھوڑ دیتی ہے۔ جدید تیاری کی تکنیک، بہتر کور مواد، اور بہتر ونڈنگ ڈیزائنز کی وجہ سے خشک قسم کے ٹرانسفارمرز مختلف آپریٹنگ حالات میں شاندار کارکردگی اور قابل اعتماد برقی کارکردگی فراہم کرنے کے قابل ہوتے ہیں۔

خشک قسم کے ٹرانسفارمرز کی برقی خصوصیات میں عمدہ وولٹیج ریگولیشن، کم ہارمونک تشکیل، اور مختلف لوڈ کی حالت میں مستحکم کارکردگی شامل ہیں۔ یہ کارکردگی کی خصوصیات خشک قسم کے ٹرانسفارمرز کو حساس الیکٹرانک لوڈز اور اعلیٰ بجلی کی معیاری ضروریات والی درخواستوں کے لیے مناسب بناتی ہیں۔ نیز، تیل کی عدم موجودگی سے بوڑھے ہونے والے تیل والے ٹرانسفارمر سسٹمز میں پائی جانے والی تیل سے متعلقہ برقی کارکردگی کی کمی کے بارے میں فکر ختم ہو جاتی ہے۔

فیک کی بات

تیل سے بھرے یونٹس کے مقابلے میں خشک قسم کے ٹرانسفارمرز کے بنیادی حفاظتی فوائد کیا ہیں

خشک قسم کے ٹرانسفارمر وہ آگ اور دھماکے کے خطرات ختم کر دیتے ہیں جو قابلِ اشتعال عزل کرنے والے تیل سے منسلک ہوتے ہی ہیں، جس سے خصوصی آگ بجھانے کے نظام کی ضرورت کم ہو جاتی ہے اور معیاری عمارت کی بنیادی سہولیات والی مختلف اندرونی جگہوں پر ان کی تنصیب ممکن ہو جاتی ہے۔ تیل کی عدم موجودگی سے رساو سے متعلق حفاظتی خطرات اور ماحولیاتی آلودگی کے خطرات بھی ختم ہو جاتے ہیں، جس کی وجہ سے یہ عملے اور سہولیات دونوں کے لیے بنیادی طور پر زیادہ محفوظ ہوتے ہیں۔

خشک قسم کے ٹرانسفارمر اور تیل والے ٹرانسفارمر میں مرمت کی ضروریات میں کیا فرق ہے؟

خشک قسم کے ٹرانسفارمر کی مرمت کی بہت کم ضرورت ہوتی ہے کیونکہ ان میں تیل سے متعلقہ طریقہ کار جیسے تیل کا نمونہ لینا، جانچنا، صاف کرنا اور تبدیل کرنا ختم ہو جاتا ہے۔ مرمت کا زیادہ تر محور بصری معائنہ اور بنیادی برقی جانچ پر ہوتا ہے، جس سے لاگت، منصوبہ بندہ غیر فعالی کے دورانیے اور روایتی تیل ٹرانسفارمر نظام کے مقابلے میں ماہر تیل ہینڈلنگ کی مہارت پر انحصار کم ہو جاتا ہے۔

کیا خشک قسم کے ٹرانسفارمر تیل سے بھرے متبادل کے مقابلے میں زیادہ ماحول دوست ہوتے ہیں؟

جی ہاں، خشک قسم کے ٹرانسفارمرز مٹی اور زمینی سطح کے پانی میں تیل کی آلودگی کے خطرات کو ختم کرکے، ریسائیکلنگ اور ختم کرنے کے طریقہ کار کو آسان بناتے ہوئے، اور تیل سے متعلقہ ماحولیاتی ضوابط کی خود بخود تعمیل کرکے بہتر ماحولیاتی کارکردگی فراہم کرتے ہیں۔ یہ پائیدار کاروباری طریقوں کی حمایت کرتے ہیں اور تیل والے ٹرانسفارمرز کی نصب کردہ نسبت طویل مدتی ماحولیاتی ذمہ داری کو کم کرتے ہیں۔

اپنی عملی عمر کے دوران خشک قسم کے ٹرانسفارمرز کن معاشی فوائد فراہم کرتے ہیں

خشک قسم کے ٹرانسفارمرز بنیادی ڈھانچے کی کم ضروریات، تیل کی مرمت ختم ہونے کی وجہ سے کم طویل مدتی آپریٹنگ اخراجات، انسٹالیشن کے آسان طریقہ کار، اور اکثر کم بیمہ پریمیمز کے ذریعے معاشی فوائد فراہم کرتے ہیں۔ ابتدائی اخراجات قابلِ موازنہ ہوسکتے ہیں، لیکن مجموعی ملکیت کی لاگت عام طور پر جاری آپریشنل بچت اور کم مرمت کی پیچیدگی کی وجہ سے خشک قسم کے ٹرانسفارمرز کے حق میں ہوتی ہے۔

مندرجات

- بہتر حفاظتی خصوصیات اور آگ کی روک تھام

- کم ترین مرمت کی ضروریات اور آپریشنل کارآمدی

- ماحولیاتی مطابقت اور پائیداری کے فوائد

- معاشی فوائد اور کل ملکیت کی کل لاگت

- فنی کارکردگی اور استعمال کے اعتبارات

-

فیک کی بات

- تیل سے بھرے یونٹس کے مقابلے میں خشک قسم کے ٹرانسفارمرز کے بنیادی حفاظتی فوائد کیا ہیں

- خشک قسم کے ٹرانسفارمر اور تیل والے ٹرانسفارمر میں مرمت کی ضروریات میں کیا فرق ہے؟

- کیا خشک قسم کے ٹرانسفارمر تیل سے بھرے متبادل کے مقابلے میں زیادہ ماحول دوست ہوتے ہیں؟

- اپنی عملی عمر کے دوران خشک قسم کے ٹرانسفارمرز کن معاشی فوائد فراہم کرتے ہیں